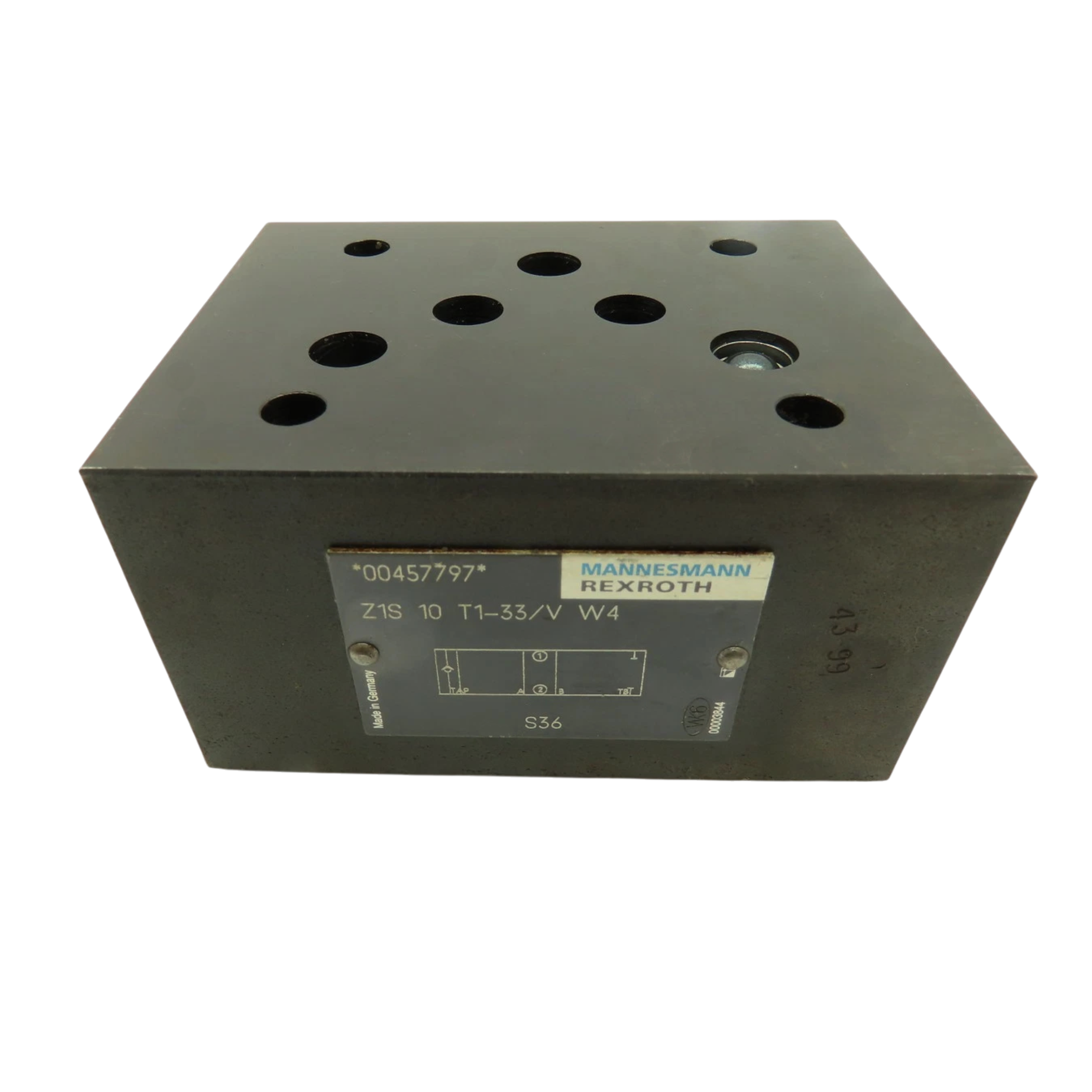

Bosch Rexroth | Z1S6C05-4XV

Z1S6C05-4X/V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The Z1S6C05-4X/V check valve is produced by Bosch Rexroth within the Z1S Check Valves series and is intended to block reverse flow in compact hydraulic manifolds for automation tasks. Its sandwich plate design lets the unit be stacked between a subplate and other directional valves, saving space and tubing. Direct-operated actuation gives an immediate response because the poppet moves directly with the pressure differential rather than through a pilot stage. Size 6 dimensions correspond to NG06 cavities, fitting small power packs and modular valve banks. A maximum operating pressure of 350 bar enables use in high-pressure circuits such as presses and metal-forming machines. The valve handles up to 40 l/min, so medium-capacity actuators can cycle without excessive pressure drop. A cracking pressure of 0.5 bar means the poppet opens with minimal back pressure, reducing energy loss during normal flow.

The component allows flow only from A1 toward A2, preventing reverse flow and maintaining load position when pumps are stopped. An ISO 4401-03-02-0-05 mounting pattern aligns with CETOP 03 subplates, while the NFPA T3.5.1 R2-2002 D03 interface provides the equivalent North American footprint for interchangeable installation. FKM seals endure elevated oil temperatures and aggressive additives, extending service life in harsh duty cycles. The valve can be mounted in any position, giving designers flexibility in manifold layout. System filtration must maintain ISO 4406 cleanliness class 20/18/15 so particulate does not damage the poppet or seat. These features combine to deliver reliable check functionality across varied industrial hydraulic systems.

Technical Specifications

Actuation

Direct-Operated

Cleanliness Class

ISO 4406 20/18/15

Cracking Pressure

0.5 bar

Direction Of Flow

A1 → A2

Installation Position

Any

Maximum Flow

40 l/min

Maximum Operating Pressure

350 bar

Mounting Pattern

ISO 4401-03-02-0-05

Nfpa Interface

T3.5.1 R2-2002 D03

Seal Material

FKM

Size

6

Valve Design

Sandwich Plate

Shipping & Payment Options