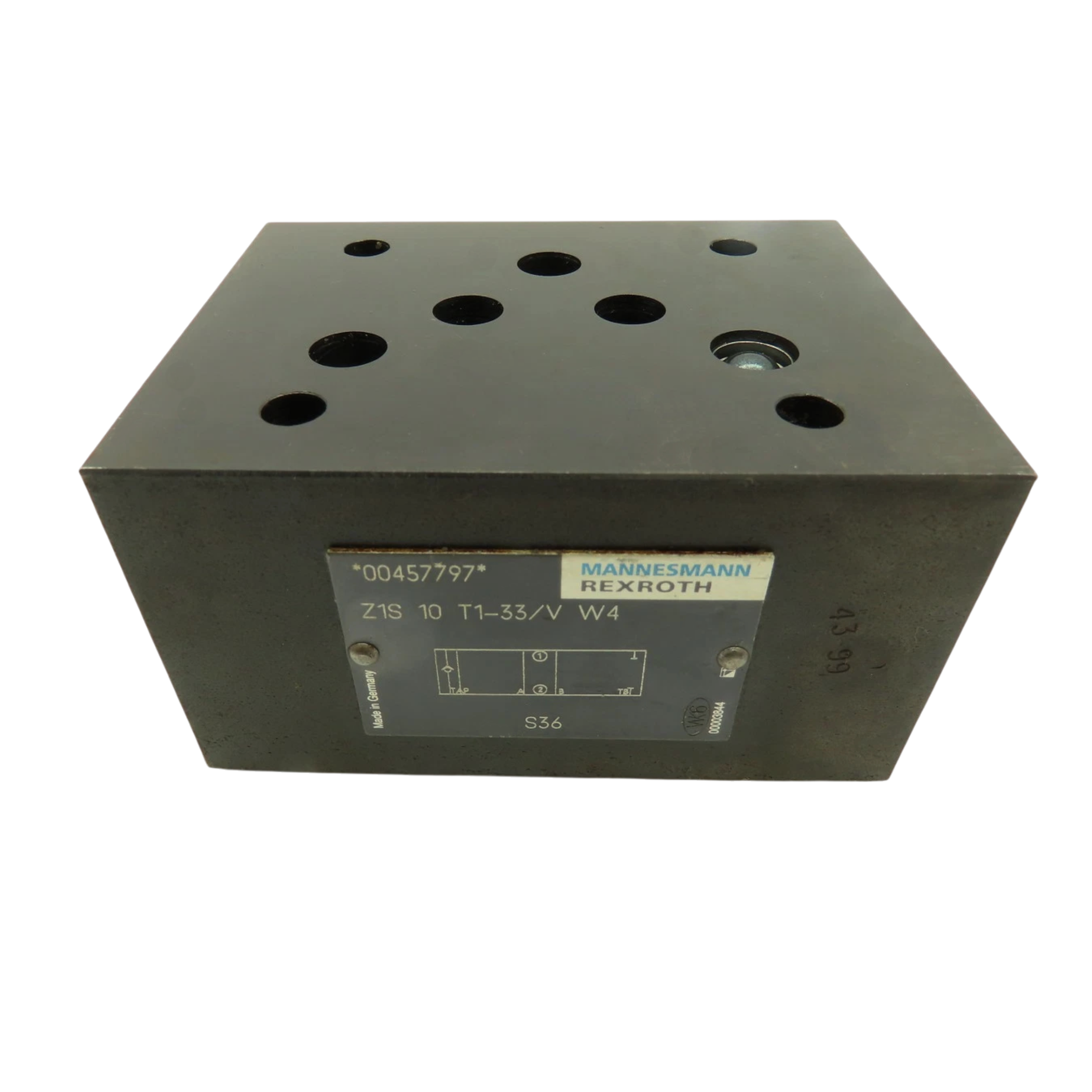

Bosch Rexroth | Z1S10TA30-2TB9-4XF

Z1S10TA30-2TB9-4X/F

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The Z1S10TA30-2TB9-4X/F is a check valve developed by Bosch Rexroth for the Z1S Check Valves series to control one-way flow in hydraulic automation manifolds. It mounts on sub-plates that follow the ISO 4401-05-04-0-05 porting pattern, while the NFPA T3.5.1 R2-2002 D05 pattern allows use with North American standard blocks. Flow is routed through the TA channel so that oil passes from port A to port T and is stopped in the reverse direction; port B remains isolated because channel Tb is closed. The element sits on the plate side in a 1→2 direction, which simplifies stacking with other sandwich valves. A cracking pressure of 3.0 bar ensures that the valve opens only after a defined upstream pressure is reached, and the body withstands continuous system pressures up to 350 bar without distortion.

The unit handles flow rates up to 100 l/min, making it suitable for medium-capacity circuits that cycle rapidly. Proper operation is supported when hydraulic fluid temperatures stay below 80 °C and the ambient environment also remains at or under 80 °C. Acceptable fluid viscosities extend to 500 mm²/s, so the valve can run with heavier oils used in mobile or industrial equipment. FKM seal material resists swelling when exposed to many synthetic or bio-based fluids, maintaining leak-free joints. No throttle nozzle is included, so pressure drop across the valve remains minimal. The design omits pilot ports X and Y and provides no measuring ports, reducing potential leakage points. Cleanliness must be held to ISO 4406 20/18/15 to protect the seat from particle damage and ensure reliable closure.

Technical Specifications

Ambient Temperature Max

+80 °C

Channel Tb State

Closed

Check Valve Channel

TA

Cleanliness Class

ISO 4406 20/18/15

Cracking Pressure (ta)

3.0 bar

Hydraulic Fluid Temp Max

+80 °C

Installation Direction (ta)

Plate Side (1→2)

Maximum Flow

100 l/min

Maximum Operating Pressure

350 bar

Measuring Ports

None

Nfpa Pattern

T3.5.1 R2-2002 D05

Pilot Ports X And Y

None

Porting Pattern

ISO 4401-05-04-0-05

Seal Material

FKM

Throttle Nozzle

None

Viscosity Max

500 mm²/s

Shipping & Payment Options