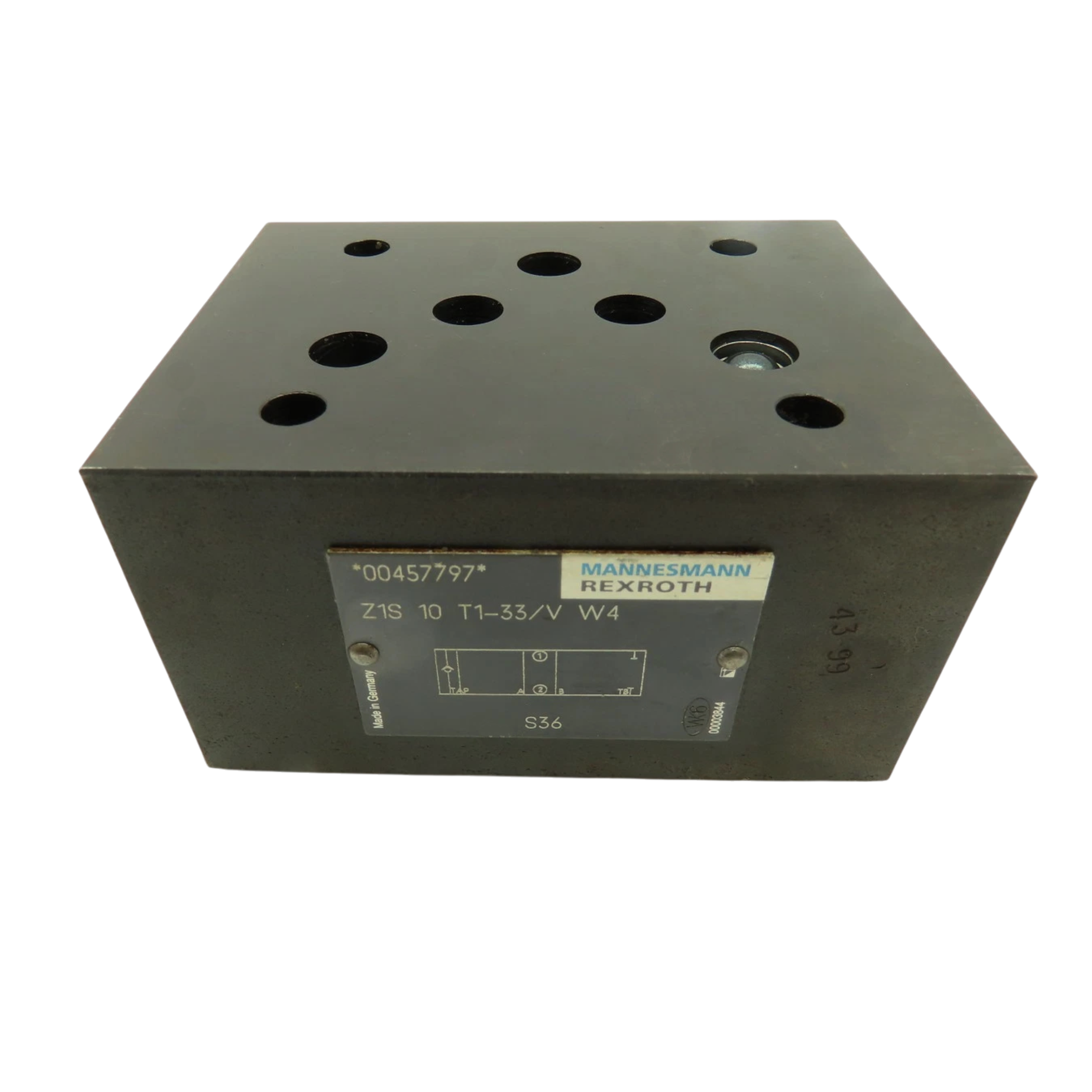

Bosch Rexroth | Z1S10B05-2-4XF

Z1S10B05-2-4X/F

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The Z1S10B05-2-4X/F check valve is produced by Bosch Rexroth within the Z1S Check Valves series. It is used in hydraulic automation to allow flow in one direction while blocking reverse flow in stack-mounted circuits. The valve is configured for channel B so it provides reverse-flow blocking only on that line in a sandwich assembly. A nominal size of 10 establishes the interface dimensions and determines the flow area in common CETOP 05 manifolds. The NFPA D05 mounting pattern together with the ISO 4401-05-04-0-05 porting layout allows direct installation between standard subplates and directional valves. Flow enters on the plate side labeled 1 and exits on port 2, which simplifies piping because the check function is built into the stack. A cracking pressure of 0.5 bar ensures the poppet opens with minimal upstream pressure, reducing energy loss, and the valve withstands operating pressures up to 350 bar for use under high-pressure directional valves in industrial presses.

Maximum flow capability is 100 l/min, enabling the unit to serve medium-sized actuators without excessive pressure drop. FKM seals are fitted to resist mineral oils and elevated temperatures commonly found in power units. The valve can be mounted in any orientation, giving designers flexibility when arranging manifold blocks. System cleanliness must be maintained at ISO 4406 class 20/18/15 to protect the poppet seat from contamination that could cause leakage. Tank ports Ta and Tb are free-flowing so return oil is not restricted by the sandwich plate. Four M6 ISO 4762 grade 10.9 screws secure the stack to maintain gasket compression under dynamic loads. There are no measuring ports, pilot oil ports, or additional nozzles, eliminating extra connections and reducing potential leak paths.

Technical Specifications

Check Valve Channel

B

Cleanliness Class

ISO 4406 20/18/15

Cracking Pressure

0.5 bar

Installation Direction

Plate Side (1→2)

Installation Position

Any

Max Flow

100 l/min

Max Operating Pressure

350 bar

Measuring Ports

None

Mounting Pattern (nfpa)

D05

Mounting Screws

4x M6 ISO 4762 10.9

Nominal Size

10

Nozzle Option

None

Pilot Oil Ports

None

Porting Pattern (iso)

4401-05-04-0-05

Seal Material

FKM

Tank Ports Ta/tb

Free-Flowing

Shipping & Payment Options