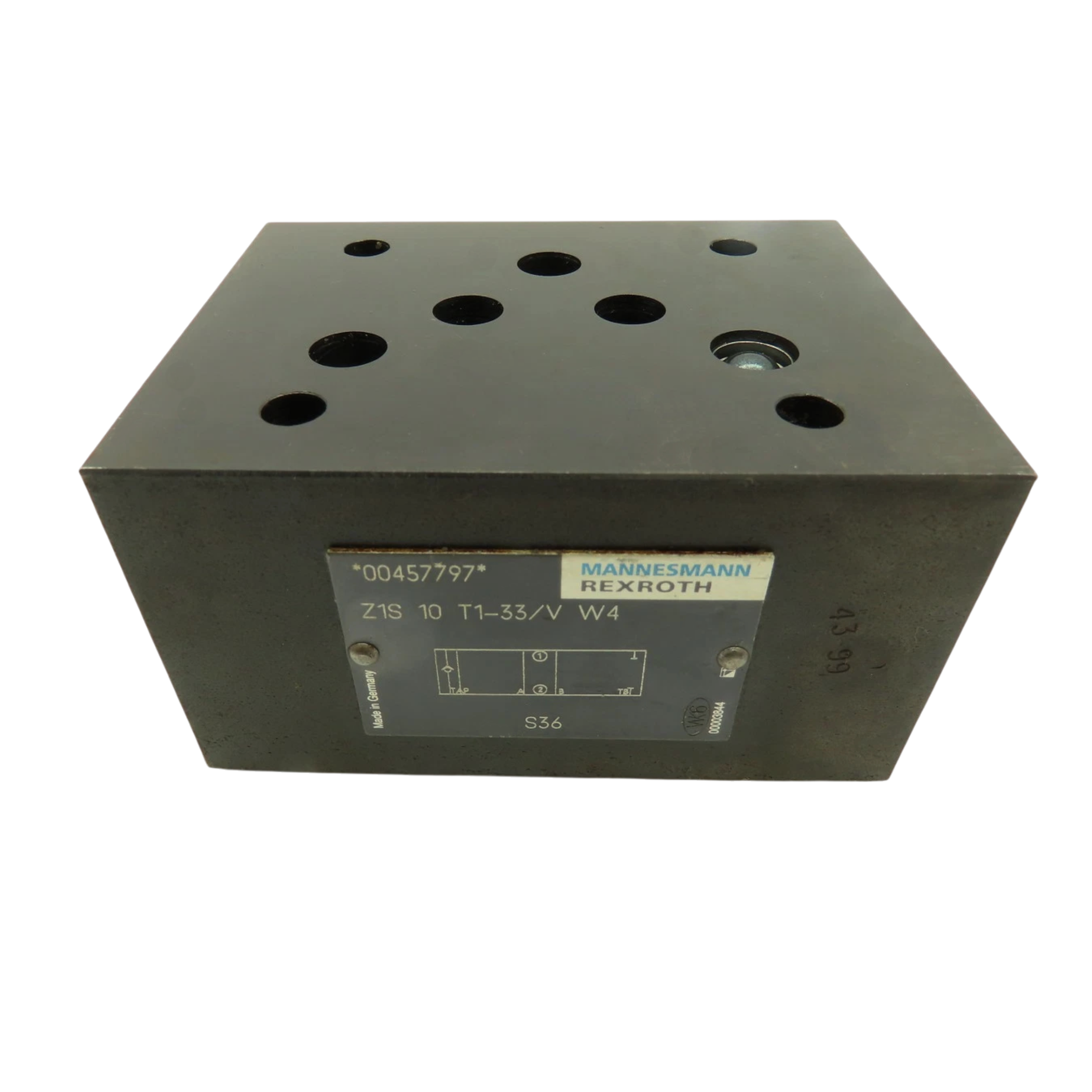

Bosch Rexroth | Z1S10A05-2B05-2-4XF

Z1S10A05-2B05-2-4X/F

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The Z1S10A05-2B05-2-4X/F check valve belongs to the Z1S Check Valves series from Bosch Rexroth and is used to prevent reverse flow in hydraulic automation circuits. Its nominal size 10 envelope matches the NFPA porting pattern T3.5.1 R2-2002 D05, allowing it to fit between standard subplates and directional valves without adapters. Check elements are provided in channels A and B to hold load pressure, while channels Ta and Tb remain free-flowing so return oil bypasses the poppets. A fixed cracking pressure of 0.5 bar lets forward flow begin with minimal energy loss, and the plate-side installation direction aligns the seats correctly inside a sandwich stack. ISO 4762 M6 grade 10.9 screws clamp the body so it safely endures a maximum operating pressure of 350 bar, and the internal passages pass up to 100 l/min without exceeding the rated flow.

Permitted fluid viscosities range from 2.8 mm²/s to 500 mm²/s, giving flexibility in oil selection for power units that run at different ambient conditions. FKM seals contain the medium across a temperature window from −20 °C to +80 °C, maintaining elasticity during cold starts and sustained high-temperature duty. The valve can be mounted in any position, which helps designers orient manifolds freely inside compact machines. System cleanliness must meet ISO 4406 code 20/18/15 so particulate matter does not damage the poppet faces or impair sealing performance. These limits on oil quality, viscosity, and temperature combine with the robust sealing material to provide consistent check action and long service life in both mobile and industrial installations.

Technical Specifications

Channels Ta/tb

Free-Flowing

Channels With Check Valves

A and B

Cleanliness Class

ISO 4406 20/18/15

Cracking Pressure (a,b)

0.5 bar

Installation Direction (a,b)

Plate Side (①→②)

Installation Position

Any

Max Hydraulic Fluid Temp

+80 °C

Max Viscosity

500 mm²/s

Maximum Flow

100 l/min

Maximum Operating Pressure

350 bar

Min Hydraulic Fluid Temp

–20 °C

Min Viscosity

2.8 mm²/s

Mounting Screws

ISO 4762 M6 10.9

Nominal Size

10

Porting Pattern (nfpa)

T3.5.1 R2-2002 D05

Seal Material

FKM

Shipping & Payment Options