Bosch Rexroth | M-4SED6D1X350CG24N9K4P

M-4SED6D1X/350CG24N9K4/P

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

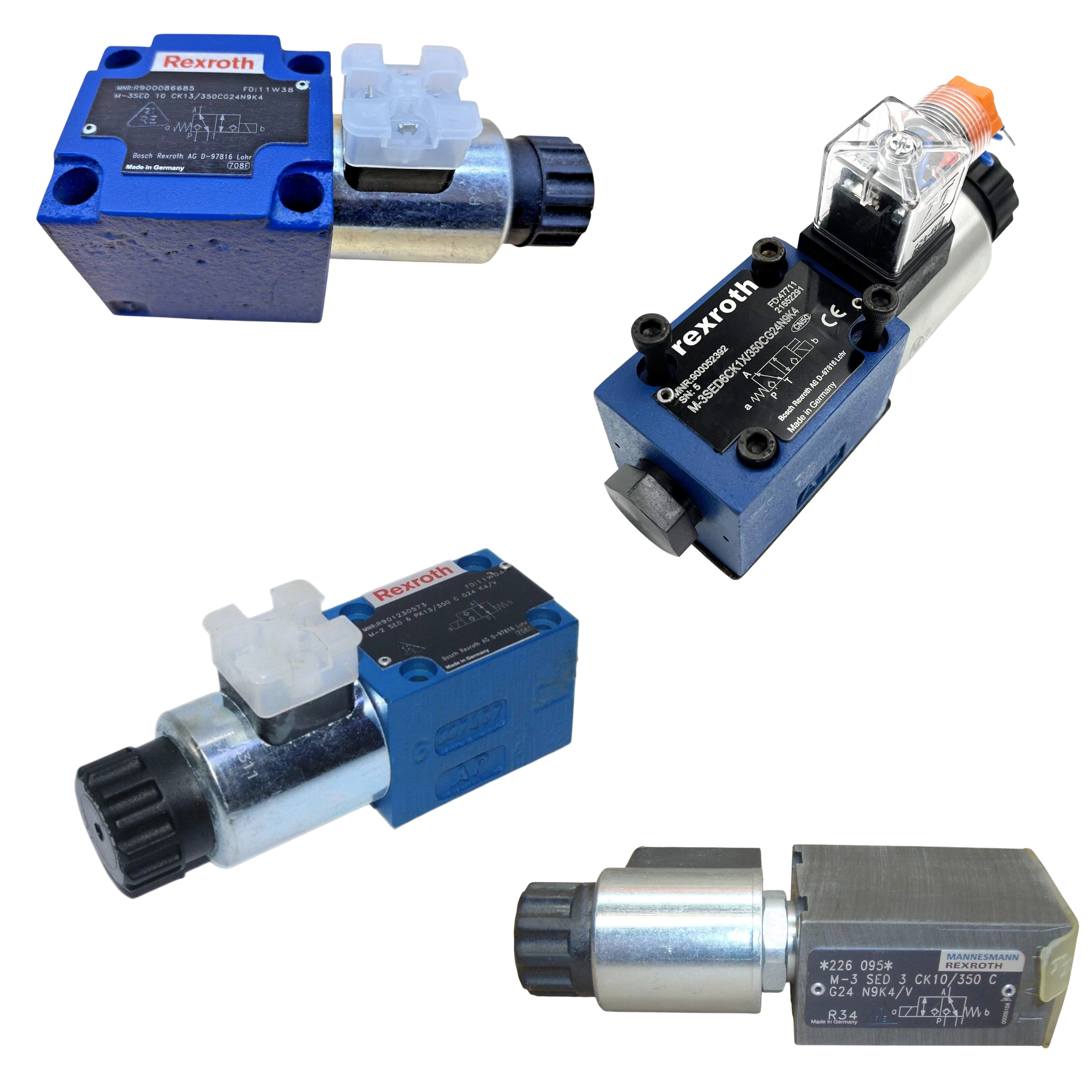

The M-4SED6D1X/350CG24N9K4/P poppet valve is produced by Bosch Rexroth for the M-SED Poppet Valves series and serves as a directional element in hydraulic automation. It uses a 4/2 variant D configuration, giving two stable positions to control four flow paths. A wet-pin, detachable coil solenoid actuates the poppet, allowing coil replacement without opening the hydraulic section. The coil is energized with a nominal supply of 24 V DC, and the circuit may vary ±10% without affecting switching reliability. Electrical load on the power supply is 30 W, keeping heat generation moderate inside the control cabinet. Connection to the wiring harness is made through a DIN EN 175301-803 type K4 plug, which standardizes pin layout and sealing. An integrated check valve insert stops reverse flow when the poppet shifts, and the hydraulic envelope tolerates operating pressures up to 350 bar for use in high-pressure manifolds.

The design supports a 100% duty cycle, allowing the solenoid to remain continuously energized during long machine cycles. Thermal limits are set by a maximum coil temperature of 150 °C, which protects insulation and winding integrity. Fast response is maintained at switching rates up to 15 000 operations per hour, enabling precise flow modulation in rapid-cycle machinery. When mated with the proper connector, the enclosure achieves an IP65 protection rating, preventing dust ingress and water jets from reaching live parts. A concealed manual override labeled N9 permits local actuation without disturbing normal sealing surfaces. System fluid must meet ISO 4406 class 20/18/15 cleanliness to avoid poppet wear or sticking. For the 4/2 function the valve requires at least 3 l/min of flow and 8 bar of inlet pressure to switch reliably, parameters that guide circuit designers when sizing pumps and orifices.

Technical Specifications

Check Valve Insert

Included

Directional Function

4/2 (Variant D)

Duty Cycle

100%

Electrical Connection

DIN EN 175301-803 (K4)

Fluid Cleanliness

ISO 4406 Class 20/18/15

Manual Override

Concealed (N9)

Max Coil Temperature

150 °C

Max Switching Frequency

15000 1/h

Maximum Operating Pressure

350 bar

Minimum Flow For 4/2 Function

3 l/min

Minimum Operating Pressure (4/2)

8 bar

Nominal Voltage

24 V DC

Power Consumption

30 W

Protection Rating

IP65 (with Mating Connector)

Solenoid Type

Wet-Pin, Detachable Coil

Voltage Tolerance

±10%

Shipping & Payment Options