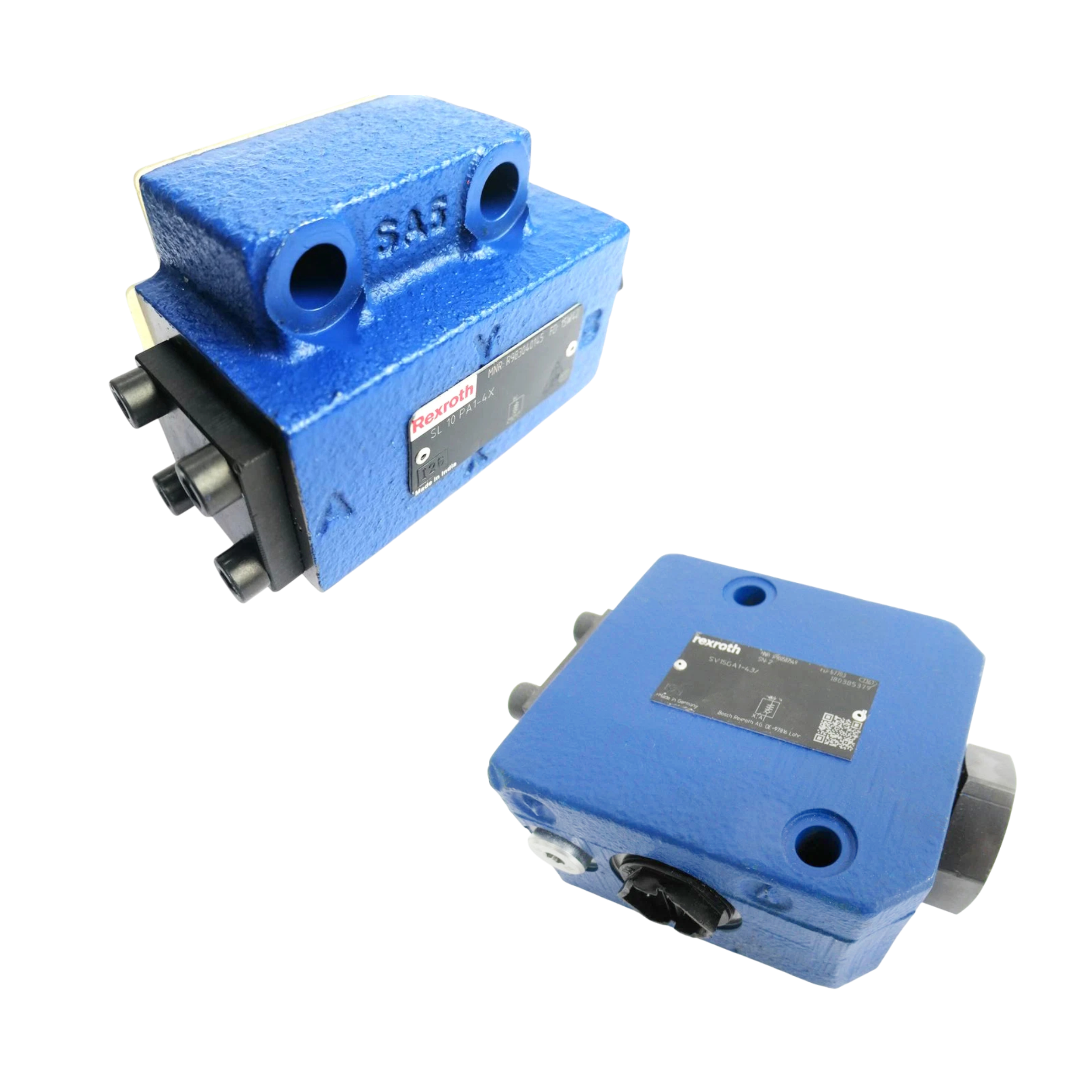

Bosch Rexroth | SL30PB1-4XV

SL30PB1-4X/V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The SL30PB1-4X/V check valve is produced by Bosch Rexroth as part of the Hy-Check Valves series. It serves in hydraulic automation circuits to permit controlled flow toward actuators while blocking return flow. The unit is built in size NG32 to match corresponding manifold cavities, and it attaches through subplate mounting using the ISO 5781-09-13-0-16 porting pattern. In operation, flow moves freely from port A to port B, while flow from port B to port A is possible only when the pilot opens the poppet, establishing directional logic. The valve opens at a cracking pressure of 2.5 bar so minimal upstream pressure is required to initiate forward flow, yet it withstands a maximum operating pressure of 315 bar to suit high-pressure installations. It accommodates flow rates up to 550 l/min without exceeding rated limits, and FKM seals are fitted to maintain compatibility with common hydraulic fluids.

The design is supplied without pre-opening, so reverse flow remains blocked until the pilot line actuates the poppet. Cleanliness requirements are limited to ISO 4406 class 20/18/15 to protect internal surfaces from abrasion. Because the installation position can be any orientation, the valve offers flexibility during manifold layout. Pilot oil returns externally, allowing separate routing of pilot fluid to tank. The pilot chamber at port X has a volume of 19.27 cm³, and the chamber at port Y holds 17.5 cm³; these values indicate the fluid capacity that must be displaced during actuation and assist in timing calculations. The subplate weighs 7.8 kg, contributing to overall assembly mass yet enabling manual handling during service. A mean time to dangerous failure of 150 years reflects the long service life expected under specified operating conditions.

Technical Specifications

Cleanliness Class (iso 4406)

20/18/15

Cracking Pressure

2.5 bar

Flow Direction

A→B Free; B→A By Opening

Installation Position

Any

Max Operating Pressure

315 bar

Maximum Flow

550 l/min

Mttfd

150 years

Pilot Oil Return

External

Pilot Volume Port X

19.27 cm3

Pilot Volume Port Y

17.5 cm3

Porting Pattern

ISO 5781-09-13-0-16

Pre-opening

Without Pre-Opening

Seal Material

FKM

Size

NG32

Type Of Connection

Subplate Mounting

Weight (subplate)

7.8 kg

Shipping & Payment Options