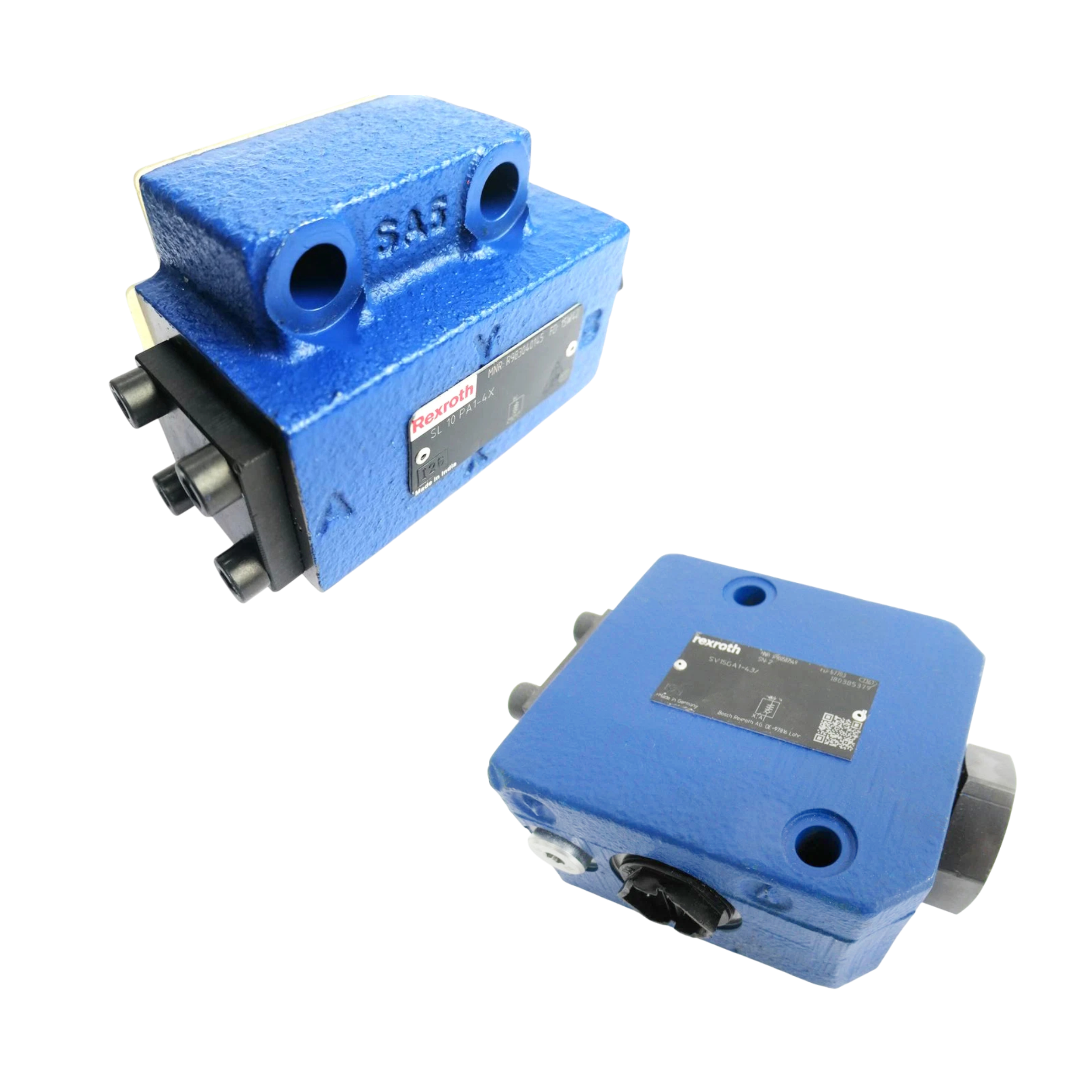

Bosch Rexroth | SL30PA3-4XV

SL30PA3-4X/V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The SL30PA3-4X/V check valve is produced by Bosch Rexroth as part of the Hy-Check Valves series for controlled blocking and pilot-assisted release of hydraulic lines in automated machinery. It is built for nominal size 32 circuits so passage dimensions match large flow paths. The valve uses subplate mounting to sit directly on a manifold block, and its porting pattern of ISO 5781-09-13-0-16 aligns the pressure passages without additional adapters. A cracking pressure of 8 bar sets the threshold at which flow from port A to port B begins, while reverse flow from port B to port A is only permitted when a 5 bar pilot signal is present. The defined flow direction—A to B free, B to A with pilot—supports accumulator isolation and load holding tasks. A pre-opening feature reduces pressure spikes by allowing a small preliminary lift of the poppet. Because the installation position can be any orientation, designers can place the valve wherever piping layout is most efficient.

The unit withstands a maximum operating pressure of 315 bar so it can sit in high-pressure supply lines common in industrial presses and injection systems. To protect internal surfaces, hydraulic fluid must meet cleanliness class ISO 4406 20/18/15, limiting solid contamination that could damage the seat. Mounting screws require 58 Nm of torque to secure the body and prevent leakage under load. Pilot oil is returned externally, simplifying vent arrangements when tank pressure fluctuates. A pilot volume of 19.27 cm³ at port X and 17.5 cm³ at port Y tells system designers how much control oil must be displaced for full poppet travel. FKM seals resist high temperature and aggressive fluids, extending service life in demanding stocks. Finally, a weight of 7.8 kg allows manual handling during assembly while still providing the mass needed for rigid seating.

Technical Specifications

Cleanliness Class

ISO 4406 20/18/15

Connection Type

Subplate Mounting

Cracking Pressure

8 bar

Flow Direction

A to B Free; B to A With Pilot

Installation Position

Any

Max Operating Pressure

315 bar

Min Pilot Pressure

5 bar

Mounting Screw Torque

58 Nm

Nominal Size

32

Pilot Oil Return

External

Pilot Volume Port X

19.27 cm3

Pilot Volume Port Y

17.5 cm3

Porting Pattern

ISO 5781-09-13-0-16

Pre-opening

Yes

Seal Material

FKM

Weight

7.8 kg

Shipping & Payment Options