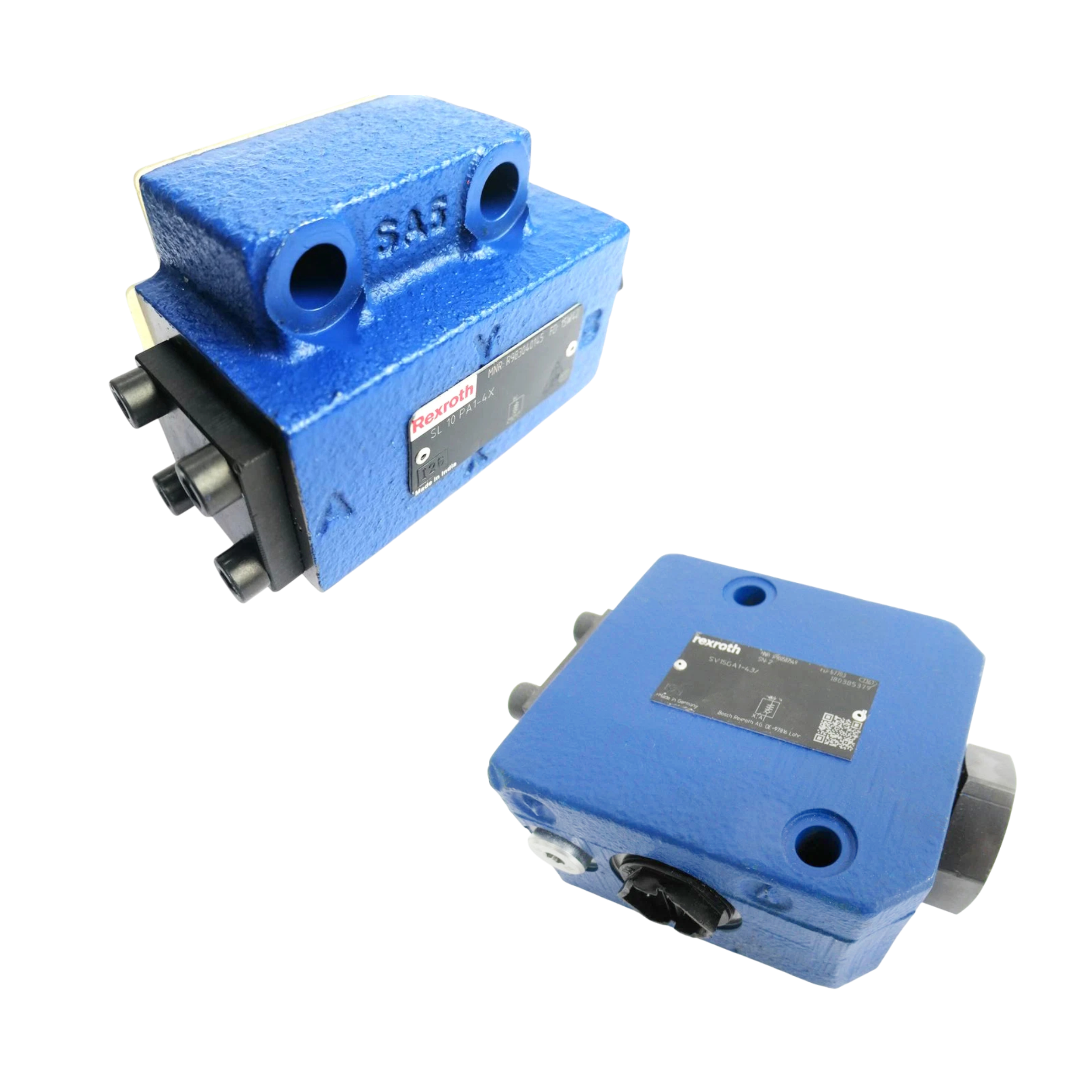

Bosch Rexroth | SL25GB3-4XV12

SL25GB3-4X/V/12

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The SL25GB3-4X/V/12 is a check valve produced by Bosch Rexroth for the Hy-Check Valves series. It is intended to block reverse flow in hydraulic automation circuits while permitting unrestricted passage from port A to port B. A nominal size of 25 defines the internal flow path and assists in matching line dimensions. The threaded connection mounting uses a UNF/UN thread, allowing direct installation into manifolds or pipework. Maximum operating pressure is 315 bar, so the unit handles high-pressure systems without deformation. The cracking action starts when inlet pressure reaches 8.0 bar because code 3 designates this opening pressure. Reverse flow is enabled only after pilot actuation; A→B is free, whereas B→A is pilot-open, supporting load holding. The component uses an FKM seal material to maintain elasticity with common hydraulic fluids, and its layout omits pre-opening features to keep the closing response firm. Control area A1 covers 5.72 cm², establishing the force required to shift the poppet under pilot influence.

Further characteristics relate to pilot control and service logistics. Control area A3 equals 16.61 cm², increasing the available surface for pilot pressure when a stronger opening force is needed. The valve needs 19.27 cm³ of oil to pressurize port X and 17.5 cm³ for port Y, volumes that help size pilot lines and timing circuits. The ratio between the two control areas, combined with the specified oil volumes, provides a predictable differential that supports synchronized unlocking across multiple lines. Pilot oil is returned externally, so designers must route a dedicated drain to tank. Cleanliness must stay at ISO 4406 class 20/18/15 to avoid wear on sealing edges and internal elastomer components. These numerical requirements allow the component to manage stored energy in accumulators or control cylinder motion with a predictable pilot signal that reliably overrides the check function.

Technical Specifications

Cleanliness Class Iso 4406 (c)

20/18/15

Connection Thread

UNF/UN

Control Area A1

5.72 cm2

Control Area A3

16.61 cm2

Control Volume Port X

19.27 cm3

Control Volume Port Y

17.5 cm3

Direction Of Flow

A→B Free; B→A Pilot-Open

Maximum Operating Pressure

315 bar

Mounting Type

Threaded Connection

Nominal Size

25

Opening Pressure (code 3)

8.0 bar

Pilot Oil Return

External

Pre-opening

Without

Seal Material

FKM

Shipping & Payment Options