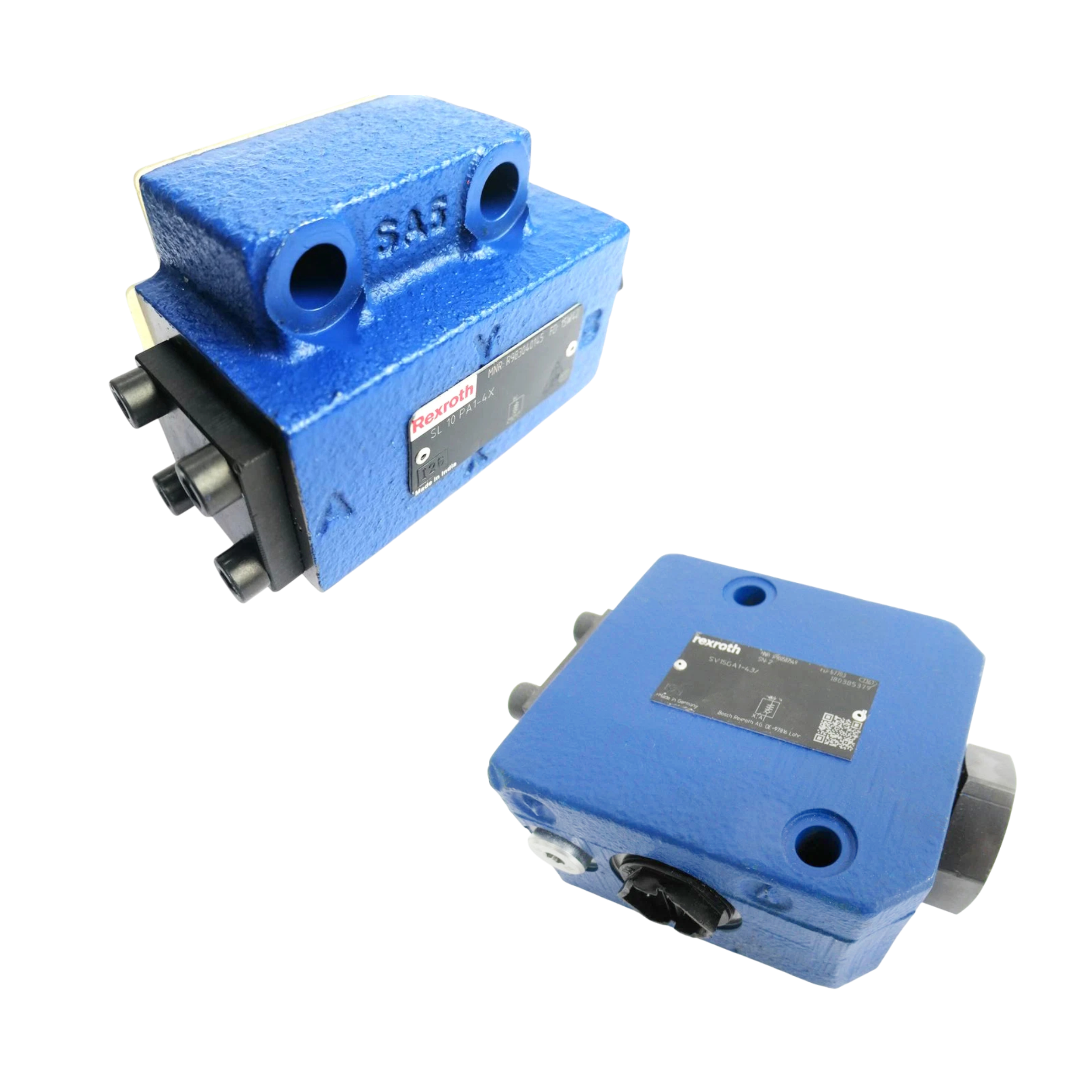

Bosch Rexroth | SL10PA2-4X

SL10PA2-4X/

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The SL10PA2-4X/ check valve is manufactured by Bosch Rexroth as part of the Hy-Check Valves series. It is intended to block or permit hydraulic flow in automated circuits based on pilot pressure commands. The valve uses porting pattern ISO 5781-06-07-0-16 so it can mount directly on standard subplates without adapter blocks. A cracking pressure of 3.0 bar ensures that flow starts only when the inlet exceeds this differential pressure. The control area A1 is 1.33 cm², setting the hydraulic force that acts on the poppet during pilot operation. To maintain reliable sealing, the hydraulic fluid must meet cleanliness class ISO 4406 (c) 20/18/15. Pilot volume at port X equals 2.5 cm³, defining the amount of oil required to shift the poppet when the valve is controlled from that side. The valve withstands continuous system pressures up to 350 bar, allowing use in high-pressure applications.

The design also tolerates pilot pressures up to 350 bar, so the control circuit can operate at full system pressure without risking damage. Installation uses four ISO 4762 M10 × 50 screws, and each screw must be tightened to 58 Nm to secure the body against its subplate. This combination of screw size, quantity, and torque distributes clamping force evenly to preserve the seal surface. The second pilot path connects to port Y, which has a volume of 2.0 cm³ and helps minimize control oil consumption when quick release is required. With a subplate-mounted weight of 1.8 kg, the valve can be fitted or removed without lifting equipment during routine service. A mean time to dangerous failure of 150 years supports long maintenance intervals and contributes to overall functional safety in hydraulic installations.

Technical Specifications

Cleanliness Class

ISO 4406 (c) 20/18/15

Control Area A1

1.33 cm2

Cracking Pressure

3.0 bar

Maximum Operating Pressure

350 bar

Maximum Pilot Pressure

350 bar

Mounting Screw Size

ISO 4762 M10 x 50

Mttfd

150 years

Pilot Volume Port X

2.5 cm3

Pilot Volume Port Y

2.0 cm3

Porting Pattern

ISO 5781-06-07-0-16

Screw Quantity

4

Tightening Torque

58 Nm

Weight (subplate Mounting)

1.8 kg

Shipping & Payment Options