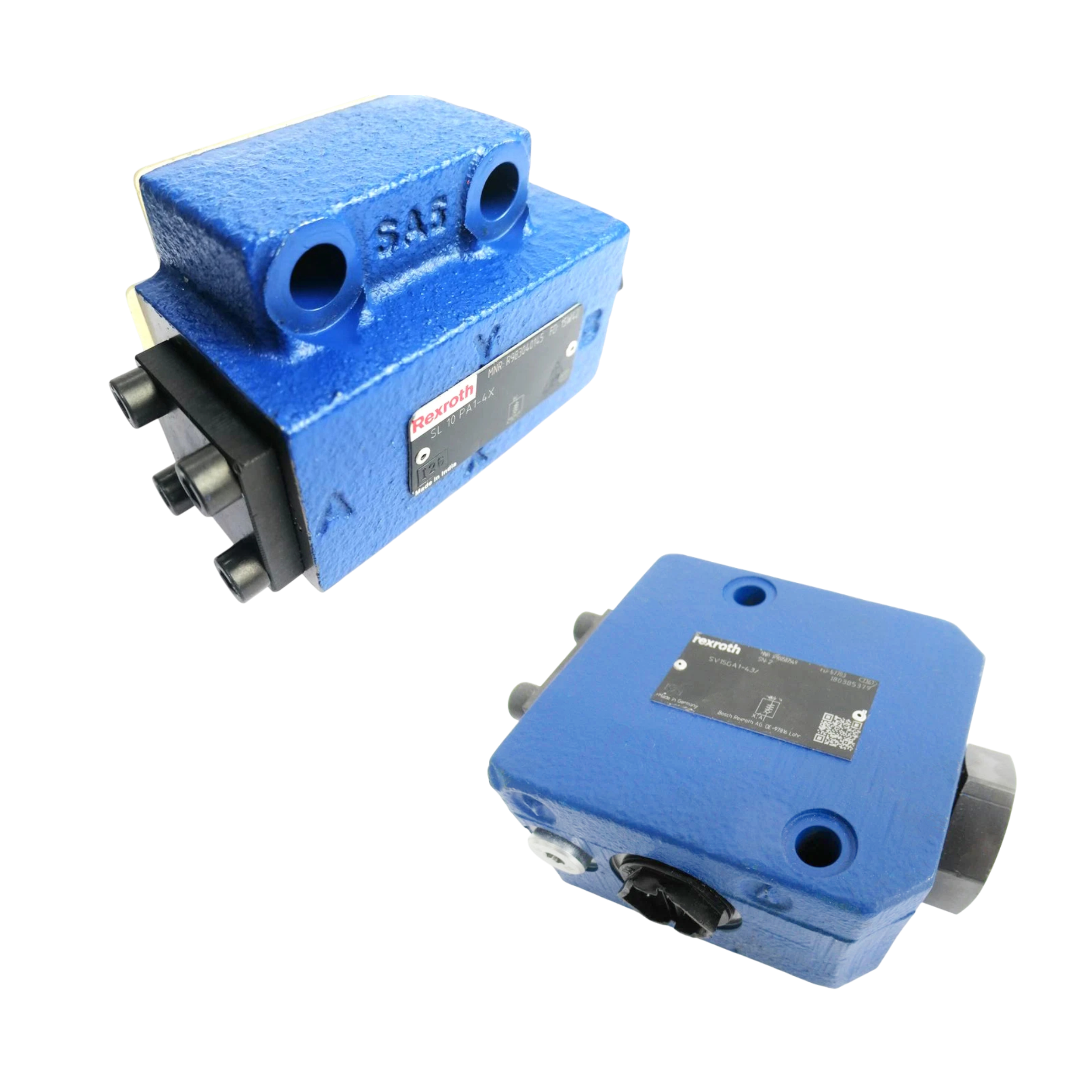

Bosch Rexroth | SL10GA3-4X

SL10GA3-4X/

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The SL10GA3-4X/ check valve is manufactured by Bosch Rexroth within the Hy-Check Valves series. Designed for hydraulic automation, the component prevents reverse flow and permits pilot-controlled reopening when needed. With a nominal size of 10, it fits NG10 cavities commonly used in medium flow circuits. A threaded connection built to ISO 228-1 simplifies installation in manifolds or line-mounted blocks. The main ports A and B are cut to G 1/2, while the pilot ports X and Y use G 1/4 threads to separate control oil from the main path. Version A includes a pre-opening feature that vents pressure peaks during rapid switching. Flow passes freely from A to B, but movement from B to A requires pilot actuation, so inadvertent backflow is blocked. A cracking pressure of 6.0 bar establishes the minimum differential before the poppet lifts. The control area A1 of 1.33 cm² defines the surface acted on by pilot pressure, determining the force needed to open the valve.

The valve withstands operating pressures up to 350 bar, allowing it to work in high-pressure power units and servo loops. A cleanliness level of 20/18/15 per ISO 4406 is required to protect the sealing edges and ensure consistent response. Because the installation position can be any orientation, designers can mount the unit wherever space is available. The pilot oil is returned externally, preventing counterpressure in the return line from influencing opening characteristics. Pilot chamber volumes are 2.5 cm³ at port X and 2.0 cm³ at port Y, figures that help predict filling times and overall switching speed in dynamic cycles. The threaded version weighs 2.1 kg, so standard pipe supports are sufficient and no additional bracket is normally needed. Together, these parameters support reliable, repeatable control of flow direction in hydraulic presses, molding machines, and other automated equipment.

Technical Specifications

Cleanliness Class

20/18/15 (ISO 4406)

Connection Type

Threaded Connection

Control Area A1

1.33 cm²

Cracking Pressure

6.0 bar

Direction Of Flow

A→B Free, B→A Pilot-Opened

Installation Position

Any

Maximum Operating Pressure

350 bar

Nominal Size

10 (NG10)

Pilot Oil Return

External

Pilot Volume Port X

2.5 cm³

Pilot Volume Port Y

2.0 cm³

Port Threads A,b

G 1/2

Port Threads X,y

G 1/4

Pre-opening

Yes (Version A)

Thread Standard

ISO 228-1

Weight (threaded Version)

2.1 kg

Shipping & Payment Options