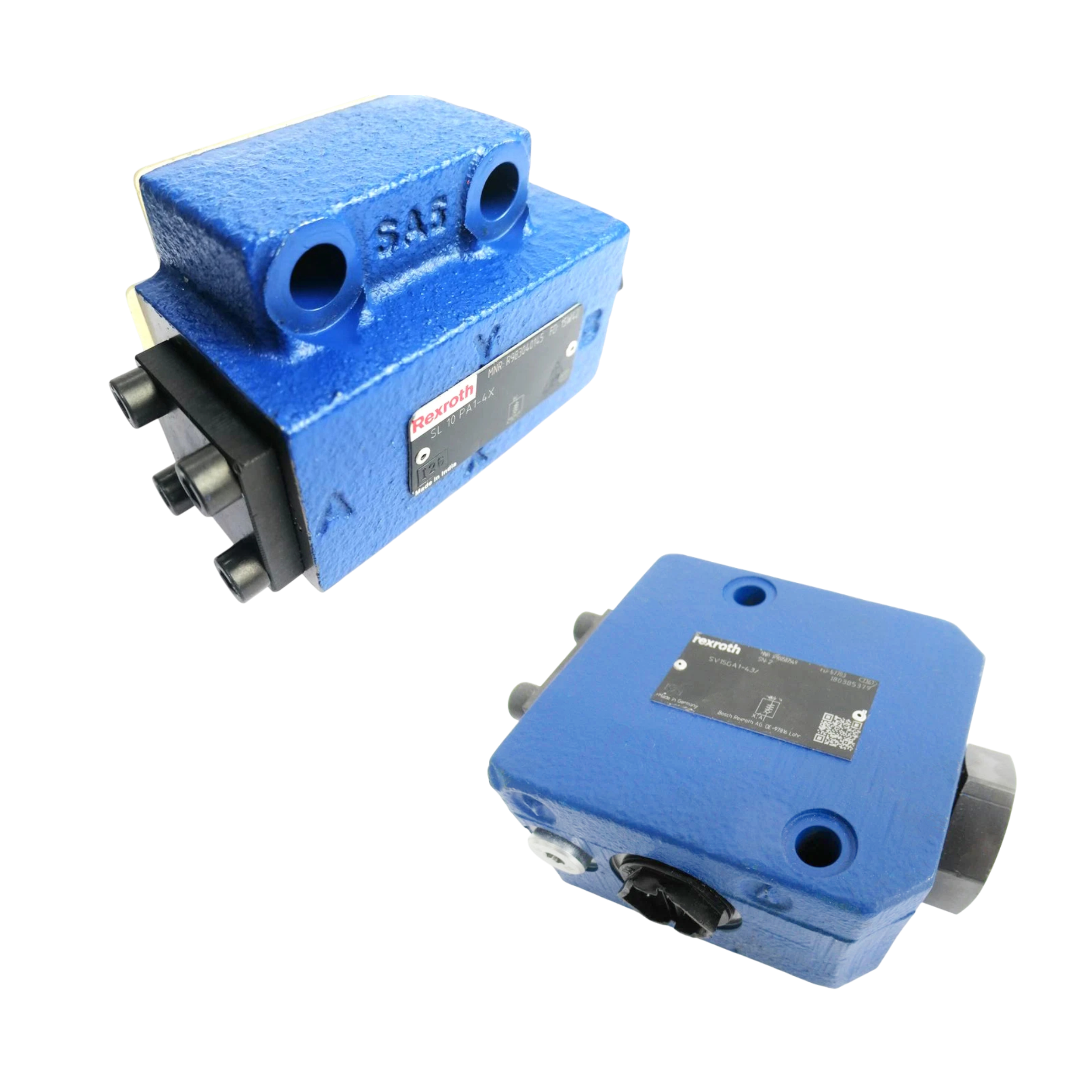

Bosch Rexroth | SL10GA2-4XV

SL10GA2-4X/V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The SL10GA2-4X/V valve belongs to the Hy-Check Valves series from Bosch Rexroth and is intended to control flow direction and pressure in automated hydraulic circuits. A nominal size of 10 (NG10) provides a passage area suited to medium-capacity lines, while the threaded connection type G simplifies direct mounting in manifolds or pipe systems. Port A/B threads are G1/2, allowing the main flow ports to match common hydraulic fittings. Flow moves freely from A to B, but B to A is blocked unless the pilot signal is present, so the valve can hold loads until commanded. A pre-opening feature on port A bleeds a small volume first, cushioning pressure surges before full poppet travel. The cracking pressure is set at 3.0 bar, establishing the minimum differential required to begin opening. A 350 bar maximum operating pressure lets the unit work in high-pressure installations, and any installation position is permitted for flexible layout. The 2.1 kg weight supports easy handling during maintenance.

The mean time to dangerous failure is rated at 150 years, giving long service life within safety-related systems. Pilot oil is returned externally through port Y so return flow does not enter the work line and disturb accuracy. A pilot volume of 2.5 cm³ at port X and 2.0 cm³ at port Y defines the fluid needed to shift the poppet, which guides circuit designers when sizing control lines. Pilot ports use G1/4 threads to fit standard small-bore tubing. An FKM seal set resists elevated temperature and aggressive fluids, extending service intervals. System cleanliness must be kept at class 20/18/15 per ISO 4406 so the seat remains free of abrasive particles and the valve closes reliably. These characteristics combine to provide stable, low-leakage check functionality under demanding hydraulic operating conditions.

Technical Specifications

Cleanliness Class

20/18/15 (ISO 4406)

Cracking Pressure

3.0 bar

Direction Of Flow

A->B Free; B->A When Piloted

Installation Position

Any

Maximum Operating Pressure

350 bar

Mttfd

150 years

Nominal Size

10 (NG10)

Pilot Oil Return

External (Port Y)

Pilot Volume Port X

2.5 cm³

Pilot Volume Port Y

2.0 cm³

Port A/b Thread

G1/2

Port X/y Thread

G1/4

Pre-opening

With Pre-Opening (A)

Seal Material

FKM

Type Of Connection

Threaded Connection (G)

Weight

2.1 kg

Shipping & Payment Options