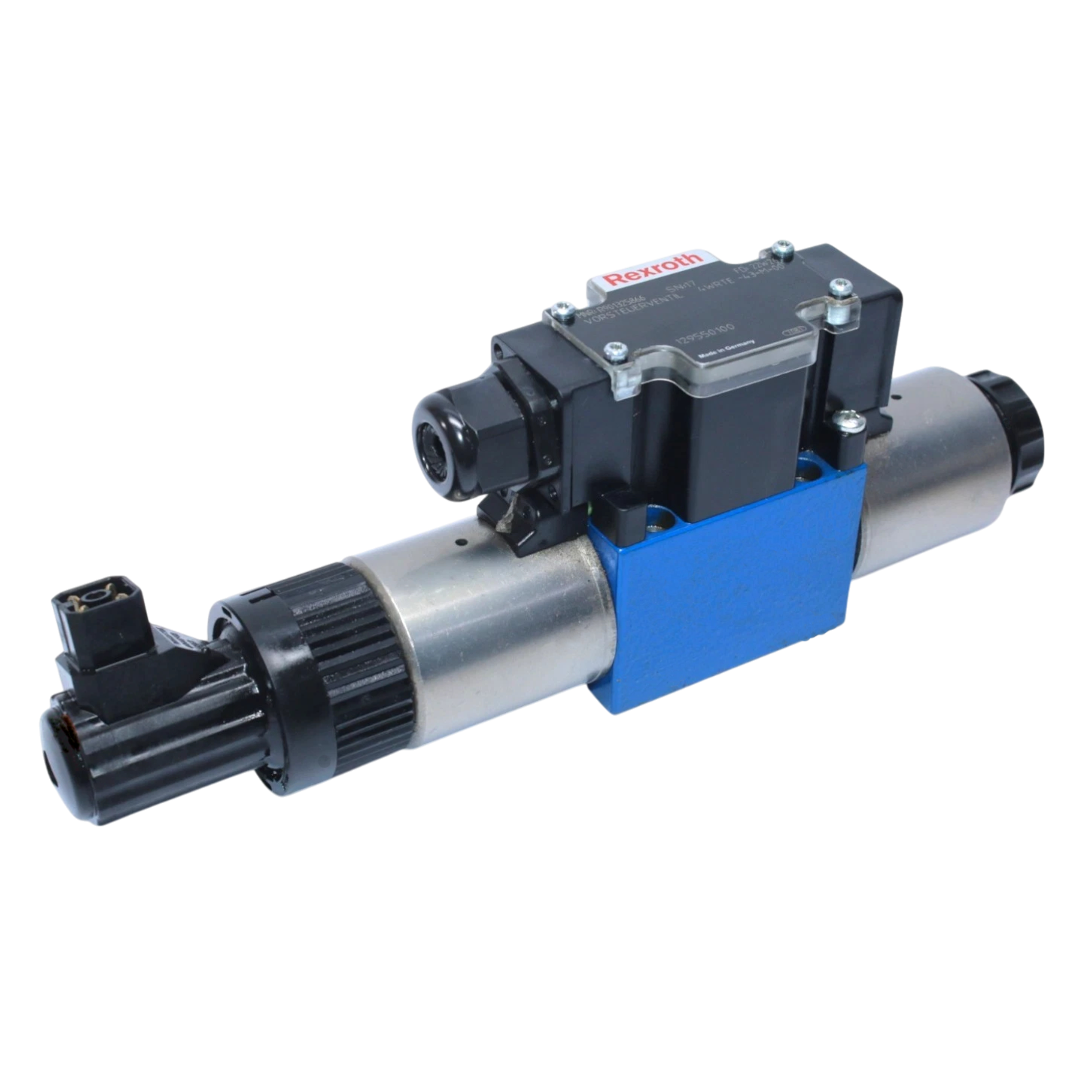

Bosch Rexroth | 4WRTE16V200L-4X6EG24ETK31F1M

4WRTE16V200L-4X/6EG24ETK31/F1M

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The 4WRTE16V200L-4X/6EG24ETK31/F1M directional control valve is produced by Bosch Rexroth in the 4WRTE Directional Control Valves series. It meters and switches hydraulic flow in automated systems where proportional control is required. The valve is built in nominal size NG16 so it can manage medium flow rates without excessive pressure loss. A maximum operating pressure of 350 bar allows it to work in high-pressure circuits common in presses, molding machines, and test rigs. The porting pattern follows ISO 4401-07-07-0-05, enabling direct mounting on standardized subplates. Internal pilot oil supply and return (ET) removes the need for external pilot lines and simplifies installation. An analog 4–20 mA electronics interface receives command signals from a PLC for precise spool positioning. The coil is energized from a 24 VDC source and draws up to 1.6 A; a 4 A time-lag fuse is specified to protect the supply wiring. Maximum apparent power reaches 72 VA, and the unit is rated for a 100 percent duty cycle, allowing continuous modulation without overheating.

Environmental and service parameters support reliable field operation. The enclosure carries an IP65 protection class, sealing the solenoid and electronics against dust and low-pressure water jets encountered in industrial plants. Electrical hookup is accomplished through a DIN EN 175201-804 connector, providing quick disconnect capability during maintenance and ensuring correct pin allocation for the two-stage pilot circuit. Hydraulic cleanliness must be maintained at ISO 4406 18/16/13 or better to prevent spool wear, control edge erosion, and erratic metering. The valve handles fluid temperatures up to 80 °C, so standard mineral oils stay within viscosity limits, while the coil itself tolerates a peak temperature of 150 °C before insulation aging accelerates. These thermal margins allow installation near hot power units. At 11.2 kg, the assembly can be lifted into place without hoists, yet its mass provides damping that minimizes resonance on vibrating machinery.

Technical Specifications

Cleanliness Class

ISO 4406 18/16/13

Current Consumption (max)

1.6 A

Electrical Connector

DIN EN 175201-804

Electronics Interface

4–20 mA

External Fuse

4 A (time-lag)

Fluid Temperature (max)

+80 °C

Max Coil Temperature

150 °C

Max Operating Pressure (p, A, B)

350 bar

Nominal Size

NG16

Pilot Oil Supply/return

Internal (ET)

Porting Pattern

ISO 4401-07-07-0-05

Power Consumption (max)

72 VA

Protection Class

IP65

Relative Duty Cycle

100%

Supply Voltage

24 VDC

Weight

11.2 kg

Shipping & Payment Options