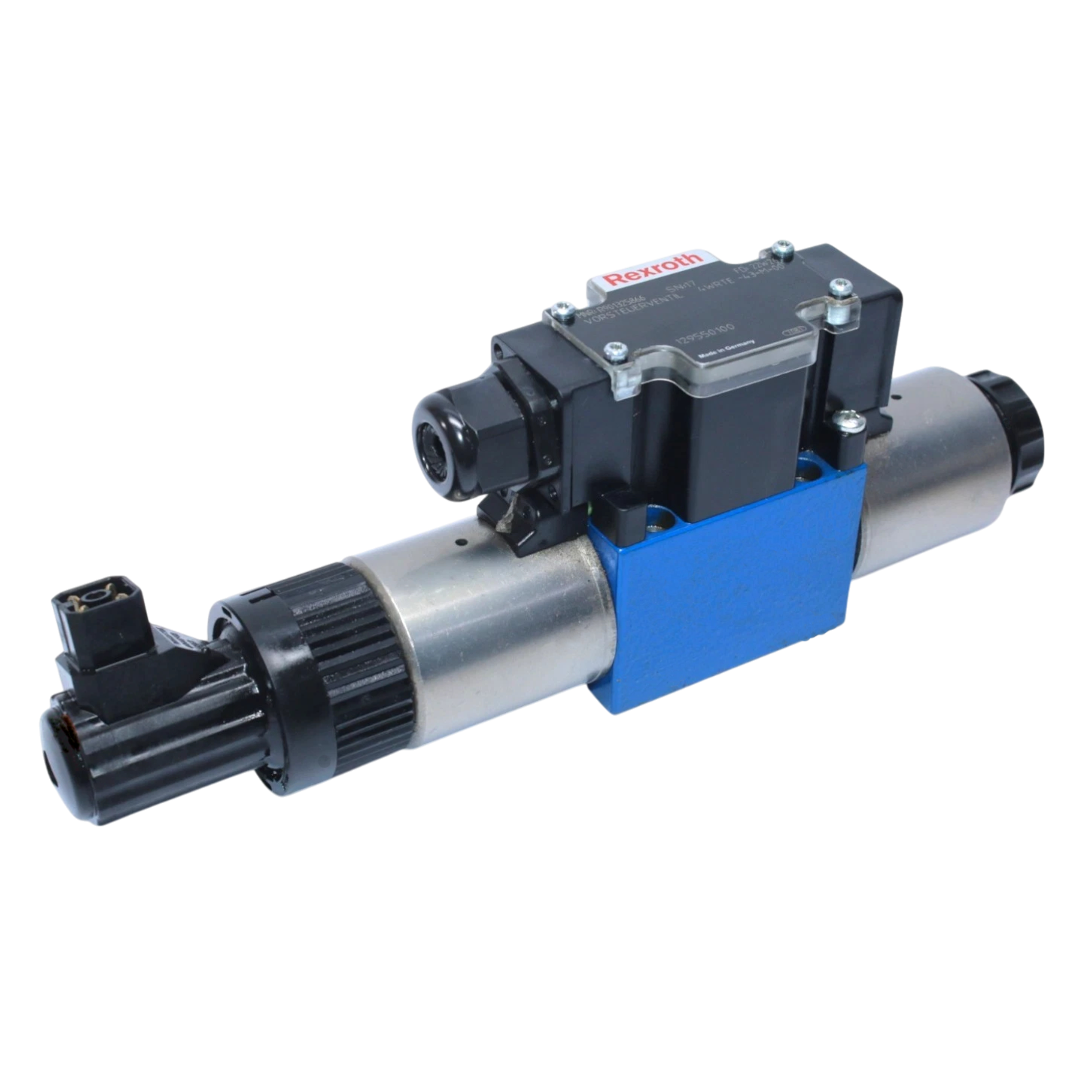

Bosch Rexroth | 4WRTE10V50L-4X6EG24ETK31A5M

4WRTE10V50L-4X/6EG24ETK31/A5M

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The 4WRTE10V50L-4X/6EG24ETK31/A5M valve is part of the 4WRTE Directional Control Valves series from Bosch Rexroth. It modulates hydraulic flow and pressure to position actuators in automated machinery. The valve is built in nominal size NG10 so it fits manifolds designed for that cavity. A rated flow of 50 l/min at a 5-bar differential across the control edge lets it handle medium-capacity circuits. The spool withstands a maximum operating pressure of 350 bar to suit high-pressure supply lines. Pilot oil is taken and returned internally, a configuration labeled ET, which removes the need for external pilot plumbing. Electronic control is provided through a ±10 V interface (code A5), and that signal sees an input resistance of 100 kΩ to minimize load on the controller. The electronics require a nominal supply of 24 VDC but remain functional down to 18 VDC, letting the device ride through brief voltage dips.

Peak current consumption is limited to 1.6 A, and the drive electronics draw at most 72 VA of power under full modulation. A continuous duty cycle of 100 percent allows the valve to stay energized without scheduled cooling periods. The internal amplifier tolerates residual ripple up to 2.5 Vpp on the supply, maintaining stable spool positioning when the DC bus is noisy. Environmental protection is rated at IP65, so the housing resists dust and low-pressure water jets common in factory wash-down zones. Return pressure in port T must stay below 10 bar, preventing back-pressure from affecting pilot stages. Hydraulic oil cleanliness must meet class 18/16/13 under ISO 4406 to avoid premature wear of metering edges. The assembly weighs 8.7 kg, which technicians should consider when selecting manifold supports.

Technical Specifications

Cleanliness Class (iso 4406)

18/16/13

Command/actual Value Interface

±10 V (A5)

Current Consumption (maximum)

1.6 A

Duty Cycle

100% (Continuous)

Input Resistance (voltage Input)

100 kΩ

Max Return Pressure (port T, Internal)

<10 bar

Maximum Operating Pressure

350 bar

Maximum Power Consumption

72 VA

Nominal Size

NG10

Pilot Oil Configuration

Internal Supply/Return (ET)

Protection Class

IP65

Rated Flow (Δp 5 Bar/control Edge)

50 l/min

Residual Ripple (max)

2.5 Vpp

Supply Voltage (nominal)

24 VDC

Supply Voltage Lower Limit

18 VDC

Weight

8.7 kg

Shipping & Payment Options