Bosch Rexroth | Z4WE10X250-1XCG96N9K4V

Z4WE10X250-1X/CG96N9K4/V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

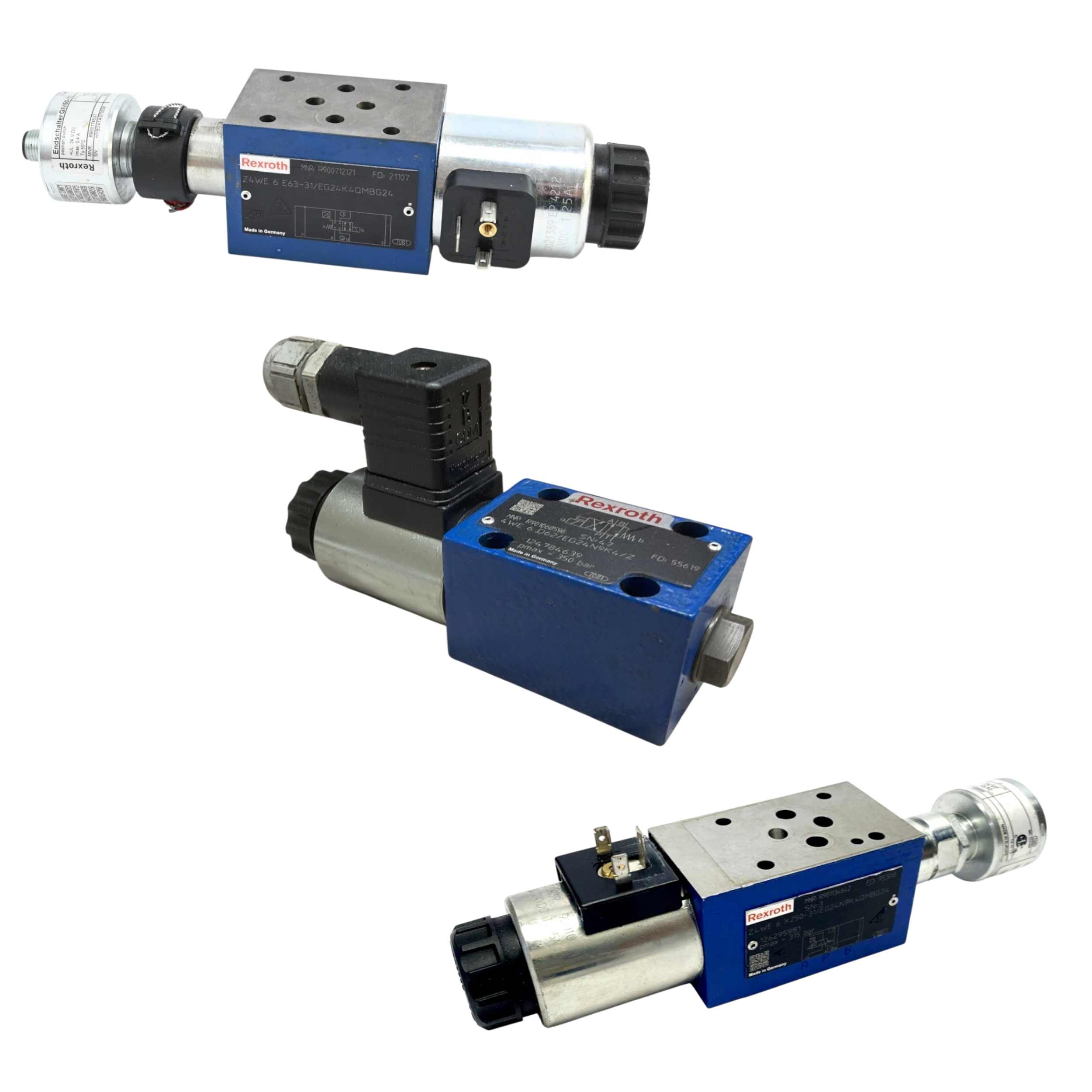

The Z4WE10X250-1X/CG96N9K4/V valve belongs to the Z4WE Solenoid Actuation Spool Valves series and is produced by Bosch Rexroth. It controls hydraulic flow by shifting a spool with an energized solenoid. The solenoid is designed for a nominal coil voltage of 96 V DC so that it can interface directly with high-voltage DC control systems. At this voltage the coil draws a rated current of 0.33 A, permitting precise power budgeting in multi-valve manifolds. Power consumption is 30 W, which defines the thermal load the housing must dissipate during continuous duty. A voltage tolerance of ±10% allows the coil to remain within performance limits despite supply variation. Operation is specified for a 100% duty cycle (S1), enabling uninterrupted actuation without mandatory cooling intervals. During de-energization the winding can withstand switch-off overvoltages up to 500 V, which protects driver electronics from transient spikes. The coil surface may reach 120 °C under worst-case heating, a value installers must consider when selecting nearby materials. An IP65 ingress protection rating prevents dust and water jets from entering the enclosure, making the valve suitable for exposed machine frames.

The pressure chambers are rated for a maximum operating pressure of 315 bar at ports P, A, and B, supporting high-pressure circuits used in presses and molding machines. Back pressure at the T port can reach 210 bar, which permits compact return-line routing without an external relief valve. The hydraulic fluid can be as cold as –15 °C and as hot as +80 °C when FKM seals are installed, allowing operation in unheated plants and warm process areas alike. Cleanliness must meet ISO 4406 class 20/18/15 so that the spool moves without scoring or sticking. Electrical connection is accomplished with a 3-pole (2+PE) plug conforming to DIN EN 175301-803, providing uniform pinout and a protective earth for the coil housing. A mean time to dangerous failure of 150 years contributes to functional-safety calculations in automated machinery. This standardized interface shortens downtime because service personnel can swap coils without rewiring. These parameters combine to define the service limits, environmental constraints, and installation needs of the valve when it is integrated into hydraulic automation systems.

Technical Specifications

Coil Power Consumption (dc)

30 W

Connector Standard

DIN EN 175301-803

Connector Type

3-pole (2+PE)

Duty Cycle

100% (S1)

Hydraulic Fluid Cleanliness Class (iso 4406)

20/18/15

Ingress Protection

IP65

Max Coil Surface Temperature

120 °C

Max Hydraulic Fluid Temp (fkm)

+80 °C

Max Operating Pressure (p,a,b)

315 bar

Max Switch-off Overvoltage

500 V

Max T Port Pressure (dc)

210 bar

Min Hydraulic Fluid Temp (fkm)

-15 °C

Mttfd

150 years

Nominal Coil Voltage

96 V DC

Rated Coil Current (96 V Dc)

0.33 A

Voltage Tolerance

±10%

Shipping & Payment Options