Bosch Rexroth | Z2FS6-7-4X2QV

Z2FS6-7-4X/2QV

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

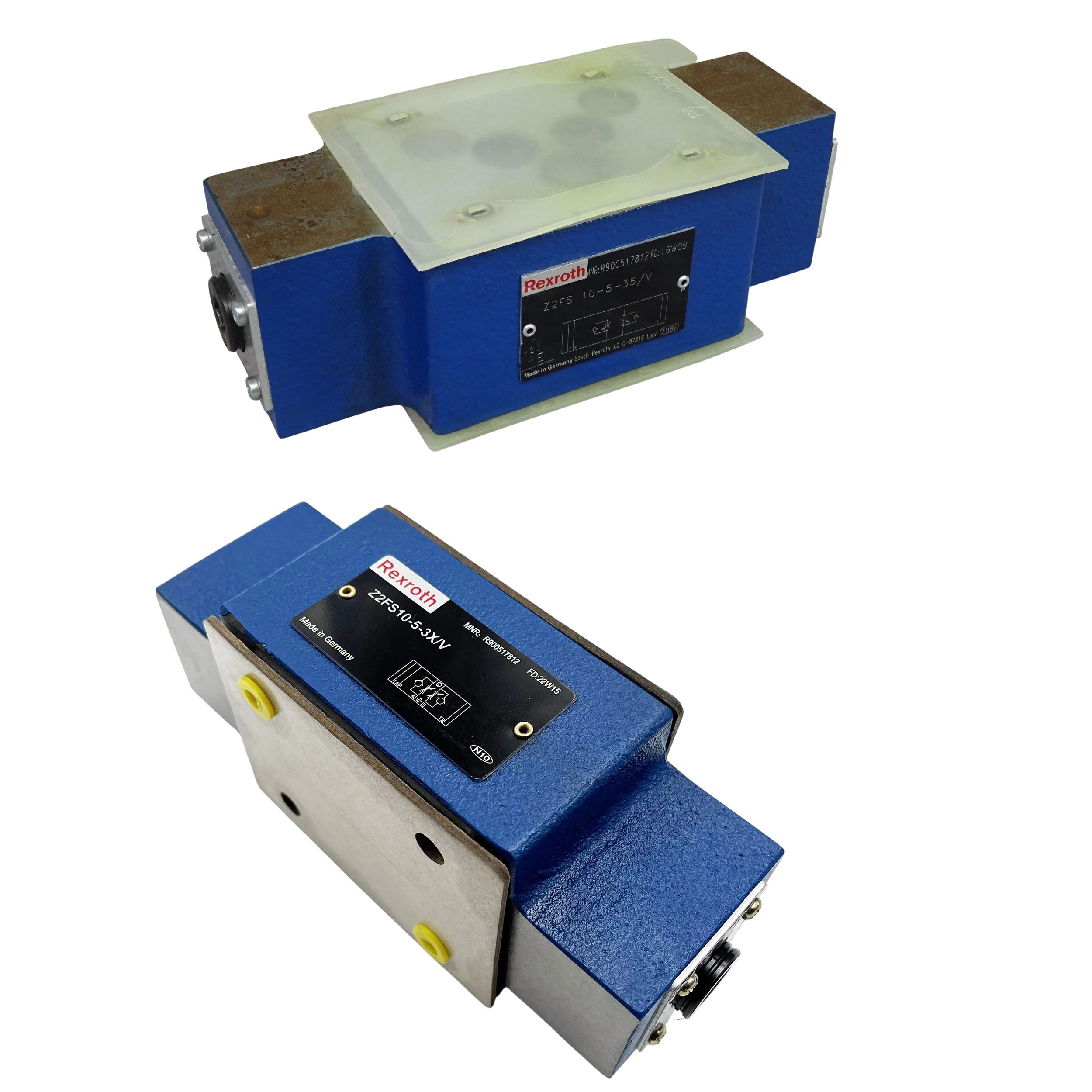

The Z2FS6-7-4X/2QV valve is produced by Bosch Rexroth as part of the Z2FS Throttle Check Valves series. It is a double throttle check valve intended to meter flow in hydraulic automation circuits while preventing reverse flow. Nominal size 6 keeps the envelope compact for D03 manifold stations, and the device follows the ISO 4401-03-02-0-05 porting pattern to match industry-standard subplates. The matching NFPA mounting pattern T3.5.1 R2-2002 D03 further simplifies interchange in North American blocks. A rotary knob with a scale lets the operator set the throttling orifice without external tools, giving repeatable adjustment when commissioning or fine-tuning motion profiles. Flow limitation acts on the main line designated 2Q so feed velocity can be reduced without affecting pilot passages. Both the A and B service ports include check elements, ensuring bidirectional load holding. The valve withstands operating pressures up to 350 bar and supports flows up to 80 l/min, allowing it to regulate medium-capacity actuators under high system pressure.

To protect the hydraulic system, the Z2FS6-7-4X/2QV accepts fluids with viscosities from 10 to 800 mm²/s and tolerates fluid temperatures between −20 °C and +80 °C while the same −20 °C to +80 °C range applies to ambient conditions around the manifold. FKM seals are fitted to resist heat and mineral-oil based media within those limits. System cleanliness must reach ISO 4406 class 20/18/15 or better so the throttling gap stays free from abrasive particles. Internal leakage remains below 1 l/min at a differential pressure of 350 bar, helping maintain actuator position accuracy and energy efficiency. Because there is no locating hole, installers must use external dowels or bolt patterns for repeatable positioning during maintenance. The specified viscosity span also covers most common mineral oils and some synthetic blends used in presses, molding machines, and mobile rigs.

Technical Specifications

Adjustment Type

Rotary Knob With Scale

Ambient Temp Range (fkm)

-20 to +80 °C

Cleanliness Class

ISO 4406 (c) 20/18/15

Flow Limitation

Main (2Q)

Fluid Temp Range (fkm)

-20 to +80 °C

Locating Hole

None

Max Flow

80 l/min

Max Leakage (Δp 350 Bar)

< 1 l/min

Max Operating Pressure

350 bar

Nfpa Pattern

T3.5.1 R2-2002 D03

Nominal Size

6

Porting Pattern

ISO 4401-03-02-0-05

Seal Material

FKM

Throttle Check Sides

A And B

Valve Type

Double Throttle Check Valve

Viscosity Range

10 to 800 mm²/s

Shipping & Payment Options