Bosch Rexroth | Z2FS16-8-3XS2V

Z2FS16-8-3X/S2V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

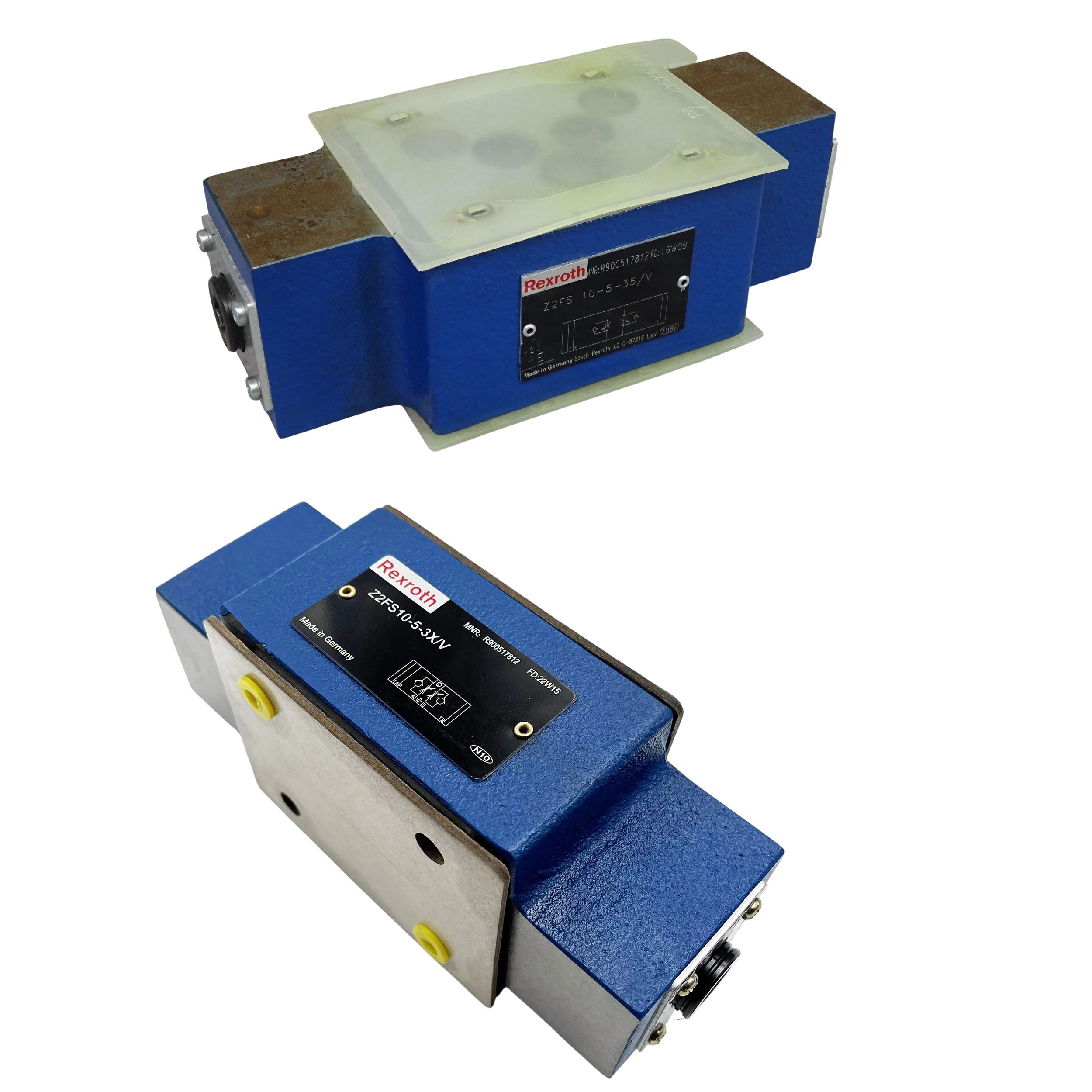

The Z2FS16-8-3X/S2V valve belongs to the Bosch Rexroth Z2FS Throttle Check Valves series and is intended to meter actuator flow in hydraulic automation circuits. It is mechanically direct-operated, so the throttling element moves in response to line pressure without auxiliary control oil. Installation is through a sandwich plate interface, enabling the unit to sit between standard sub-plates and directional valves in a stack. The nominal size 16 interface defines orifice dimensions and matches the flow paths of D07 manifolds. Conformance to the CETOP D07 standard secures bolt alignment for European equipment, while the NFPA T3.5.1 R2-2002 D07 pattern supports the same footprint for North American assemblies. An ISO 4401-07-07-0-05 porting pattern keeps manifold port positions consistent across international builds. The design provides four separate ports, letting the valve meter fluid on both service lines without external piping changes.

The valve tolerates a maximum flow of 250 l/min, giving enough capacity for medium-to-high power actuators while minimizing pressure loss. A maximum operating pressure of 350 bar allows the unit to serve in high-pressure industrial machines without structural fatigue. Throttling occurs on the discharge side of both A and B lines, so pressure spikes are damped before oil returns to the tank. The spool symbol A2→A1, B2→B1 depicts this reduction path and aids circuit diagrams during design reviews. Flow is adjusted with a spindle that has an internal hexagon, making it possible to set the orifice size with a standard Allen key even in confined panels. FKM seals provide chemical and heat resistance, maintaining leakage control when fluids run at elevated temperatures. A mass of 4.38 kg ensures the sandwich plate remains rigid in the stack and aligns accurately under tightening torque.

Technical Specifications

Actuation

Mechanical (direct operated)

Adjustment Type

Spindle (internal hexagon)

Cetop Size

D07

Connection Type

Sandwich plate

Max Flow

250 l/min

Max Operating Pressure

350 bar

Nfpa Port Pattern

T3.5.1 R2-2002 D07

Nominal Size

16

Porting Pattern

ISO 4401-07-07-0-05

Ports

4

Seal Material

FKM

Spool Symbol

A2→A1, B2→B1

Throttling Mode

Discharge (A and B)

Weight

4.38 kg

Shipping & Payment Options