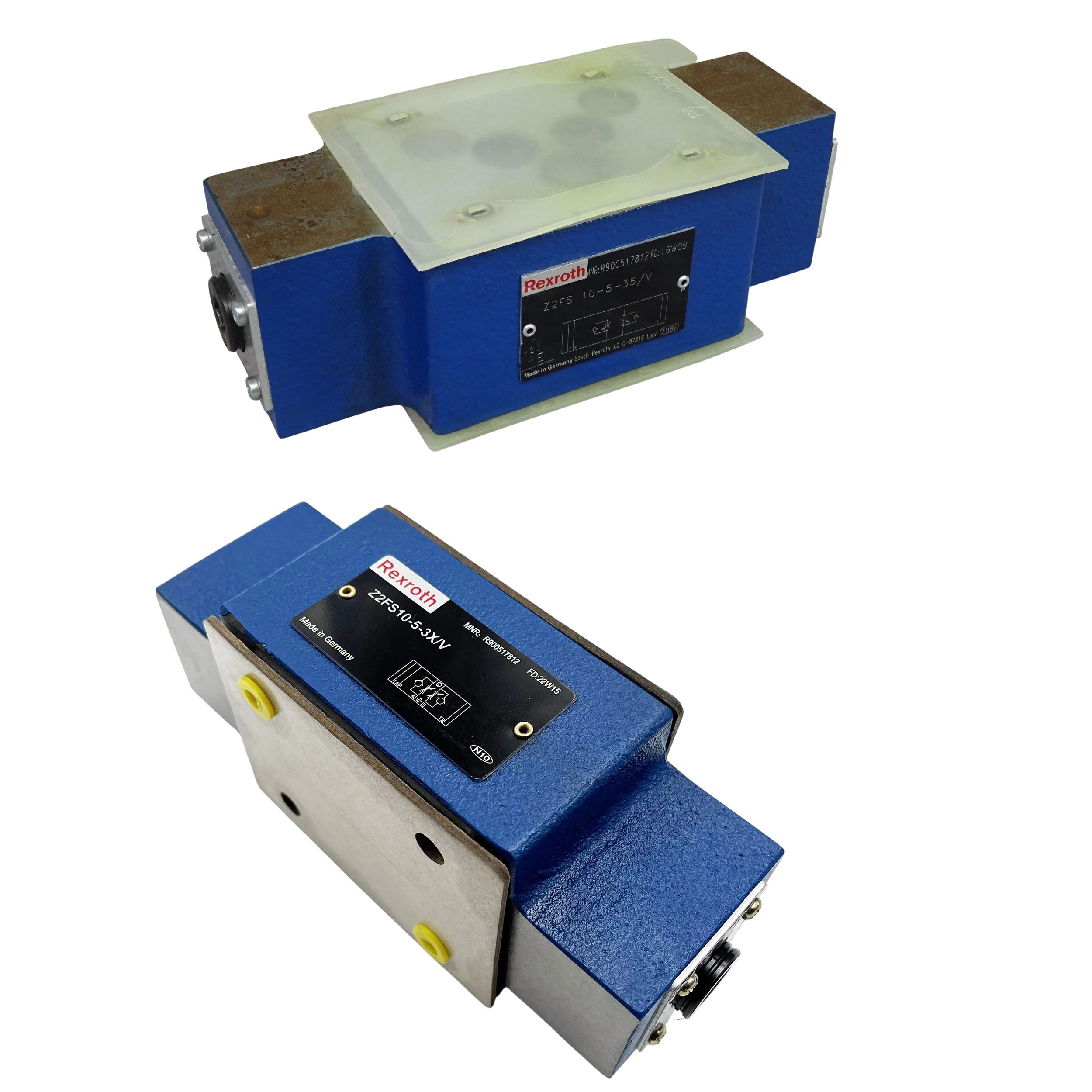

Bosch Rexroth | Z2FS10-5-3XV-SO30

Z2FS10-5-3X/V SO30

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The Z2FS10-5-3X/V SO30 is produced by Bosch Rexroth and forms part of the Z2FS Throttle Check Valves series. It provides adjustable throttling and reverse-flow check functions for hydraulic automation tasks. Valve size NG10 defines the interface dimensions and ensures compatibility with size-10 subplates. The porting pattern ISO 4401-05-04-0-05 aligns the pressure and tank channels with international manifold standards. Compatibility with ANSI pattern B93-7 D05 and NFPA pattern T3.5.1 R2 simplifies interchange with North American blocks. A bolt hole pattern of 80 × 70 mm positions the mounting screws without additional drilling. Pilot oil is routed through channels X and Y, allowing the two throttle stages to operate independently of main flow. A port P diameter of 10 mm balances flow capacity with compact form. Flow is set by a spindle that includes an internal hexagon and a scale, giving clear visual feedback during adjustment. The hex key dimension SW8 specifies the tool size required to turn the spindle. The valve can be installed in any position, which eases circuit design in confined spaces. Meeting cleanliness class ISO 4406 20/18/15 protects the throttling edges from particulate wear.

A continuous flow of up to 160 l/min can pass through the metering orifices without exceeding design limits. The assembly sustains operating pressures as high as 315 bar, so it suits main pressure lines in presses or injection units. For water-glycol fluids, the differential pressure across the throttling section may reach 210 bar while maintaining stable performance. Fluid temperature may rise to 60 °C in HFC media without compromising structural integrity. FKM seals resist this thermal load and keep leakage low when exposed to aggressive additives. These pressure, temperature, and sealing parameters combine to deliver consistent damping of flow surges. High permissible working values also allow the valve to be installed directly in pump circuits without separate safety devices. Dependable sealing reduces maintenance intervals in production cells that operate around the clock. The predictable pressure drop across the adjustable orifices supports precise actuator synchronization in closed-loop speed control. All these hydraulic limits complement the dimensional and mounting data introduced earlier to present a balanced component for demanding automation systems.

Technical Specifications

Adjustment Hex Size

SW8

Adjustment Type

Spindle with internal hexagon and scale

Ansi Pattern

B93-7 D05

Bolt Hole Pattern

80 x 70 mm

Cleanliness Class

ISO 4406 20/18/15

Installation Position

Any

Max Differential Pressure (hfc)

210 bar

Max Flow

160 l/min

Max Fluid Temperature (hfc)

60 °C

Max Operating Pressure

315 bar

Nfpa Pattern

T3.5.1 R2

Pilot Oil Duct

Via channel X and Y

Port Diameter P

10 mm

Porting Pattern

ISO 4401-05-04-0-05

Seal Material

FKM

Valve Size

NG10

Shipping & Payment Options