Bosch Rexroth | H-4WMM16E7X

H-4WMM16E7X

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

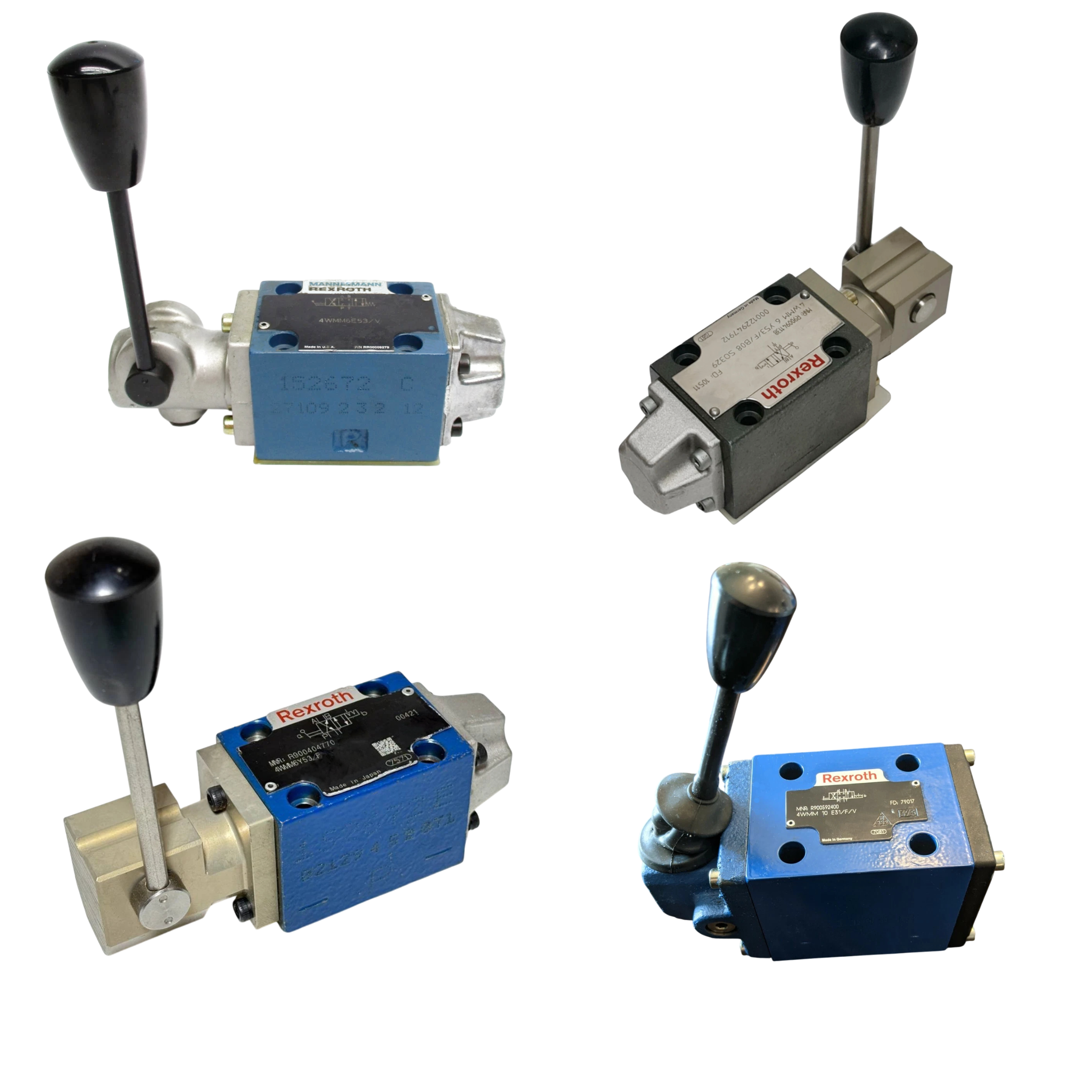

The H-4WMM16E7X directional spool valve belongs to the WM Directional Spool Valves series from Bosch Rexroth and directs hydraulic flow in automation circuits. It is shifted with a hand lever, enabling manual control when electrical actuation is not available. The spool offers 3 stable positions so that operators can select neutral, extend, or retract flow paths. There are 4 ports labeled A, B, P, and T, allowing supply, work, and tank connections common to industrial manifolds. From the centered neutral spot the lever can move through two angles of 26°, giving a defined travel range for each direction. Returning the lever to center requires a spring force that peaks at 75 N, limiting operator effort. Fluid can pass through spool type E at rates up to 300 l/min without exceeding pressure drop limits. The valve body withstands 350 bar on the A, B, and P lines while the T port is limited to 250 bar, matching typical high-pressure systems.

The unit fits subplates machined to DIN 24340 Form A16, so installation aligns with widely used CETOP 07 manifolds. Its porting pattern follows ISO 4401-07-07-0-05, ensuring compatibility with standard gasketed interfaces. Secure attachment is achieved with four M10 × 60 grade 10.9 mounting screws that must be tightened to 75 Nm. Two supplementary M6 × 60 grade 10.9 screws are specified for additional clamping and are torqued to 12.5 Nm. The mounting face is ground to a maximum surface roughness of Rz 4, which helps to maintain seal integrity when exposed to high pressure. Hydraulic cleanliness should not exceed ISO 4406 class 20/18/15 to avoid premature wear of the spool and lands. Together these geometric and contamination limits support reliable cycling within automated press, molding, and test rigs. By respecting the specified torque values and cleanliness levels, maintenance personnel can preserve the designed performance envelope for high-flow service.

Technical Specifications

Actuating Angle From Center

2 x 26°

Actuation Type

Hand Lever

Additional Screws

2 x M6 x 60 (10.9)

Cleanliness Class (iso 4406)

20/18/15

Max Actuating Force (spring Return)

75 N

Max Flow (spool E)

300 l/min

Max Operating Pressure (a/b/p)

350 bar

Max Tank Port Pressure (t)

250 bar

Mounting Pattern

DIN 24340 Form A16

Mounting Screws

4 x M10 x 60 (10.9)

Porting Pattern

ISO 4401-07-07-0-05

Ports

4 (A, B, P, T)

Spool Positions

3

Surface Roughness (mounting Face)

Rzmax 4

Tightening Torque (m10)

75 Nm

Tightening Torque (m6)

12.5 Nm

Shipping & Payment Options