Bosch Rexroth | H-4WEH25J6X6EW110N9ETDALB10D3V

H-4WEH25J6X/6EW110N9ETDAL/B10D3V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

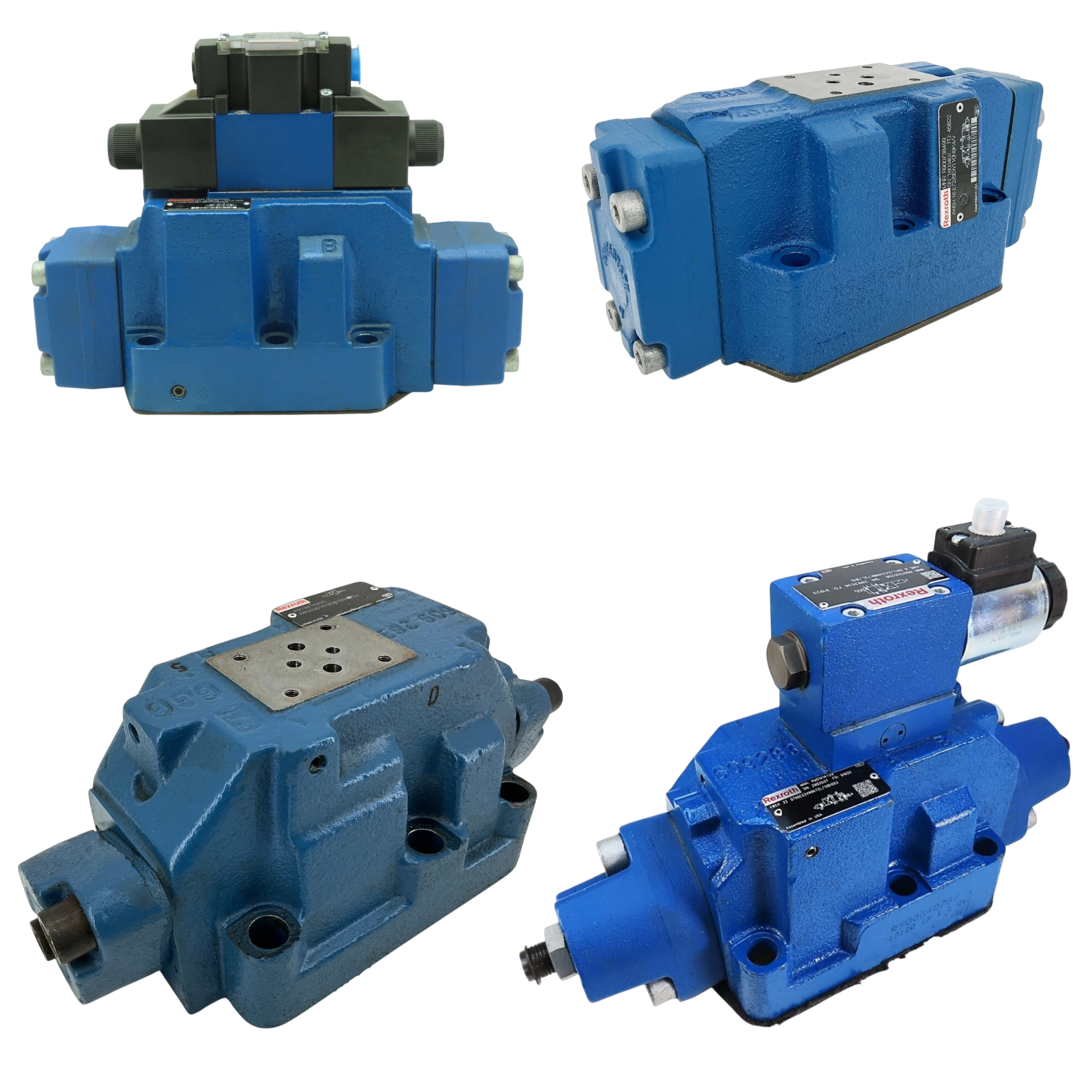

The H-4WEH25J6X/6EW110N9ETDAL/B10D3V valve is produced by Bosch Rexroth under the WEH Directional Spool Valves series for hydraulic automation that requires accurate flow control. It is an electro-hydraulic unit, so an electrical signal shifts the spool while pilot oil provides the force needed for movement. A 4-way flow path lets the valve connect pressure, tank, and two actuator ports for bidirectional cylinder drive. The NG25 nominal size determines passage dimensions suited to medium-to-high flow rates, and the J spool shape establishes the overlap and metering edges used during shifting. Three spring-centered positions return the spool to a neutral center when the solenoids are de-energized, maintaining safety during power loss. The assembly tolerates system pressures up to 350 bar and accepts pilot pressures up to 250 bar, while operation of the spring-centered design starts at a minimum pilot pressure of 13 bar. Subplate mounting eases replacement without disturbing pipework, and the ISO 4401-08-08-0-05 porting pattern aligns the valve with standardized manifold layouts.

Internal pilot oil supply and return, identified by the ET code, eliminate external pilot lines and reduce the number of leak points in the installation. The concealed N9 manual override allows service personnel to shift the spool mechanically without exposing the mechanism to contaminants. System cleanliness must be maintained at 20/18/15 per ISO 4406 to prevent wear in the precision-ground lands. A throttle insert with a 1.0 mm orifice can be fitted to dampen transient flow and avoid pressure shocks downstream. When installed, an internal pressure-reducing stage limits secondary pressure to 45 bar so pilot circuits stay within component limits even if the main line pressure rises. These features complete the functional profile and ensure reliable performance in automated hydraulic machinery.

Technical Specifications

Actuation Type

Electro-Hydraulic

Cleanliness Class

20/18/15 (ISO 4406)

Manual Override

Concealed (N9)

Max Operating Pressure

350 bar

Max Pilot Pressure

250 bar

Min Pilot Pressure (spring-centered)

13 bar

Mounting Type

Subplate Mounting

Nominal Size

NG25

Pilot Oil Return

Internal (ET)

Pilot Oil Supply

Internal (ET)

Porting Pattern

ISO 4401-08-08-0-05

Pressure Reducing Valve Secondary Pressure

45 bar

Spool Positions

3-Position (Spring-Centered)

Spool Symbol

J

Throttle Insert Diameter

1.0 mm

Way Configuration

4-Way

Shipping & Payment Options