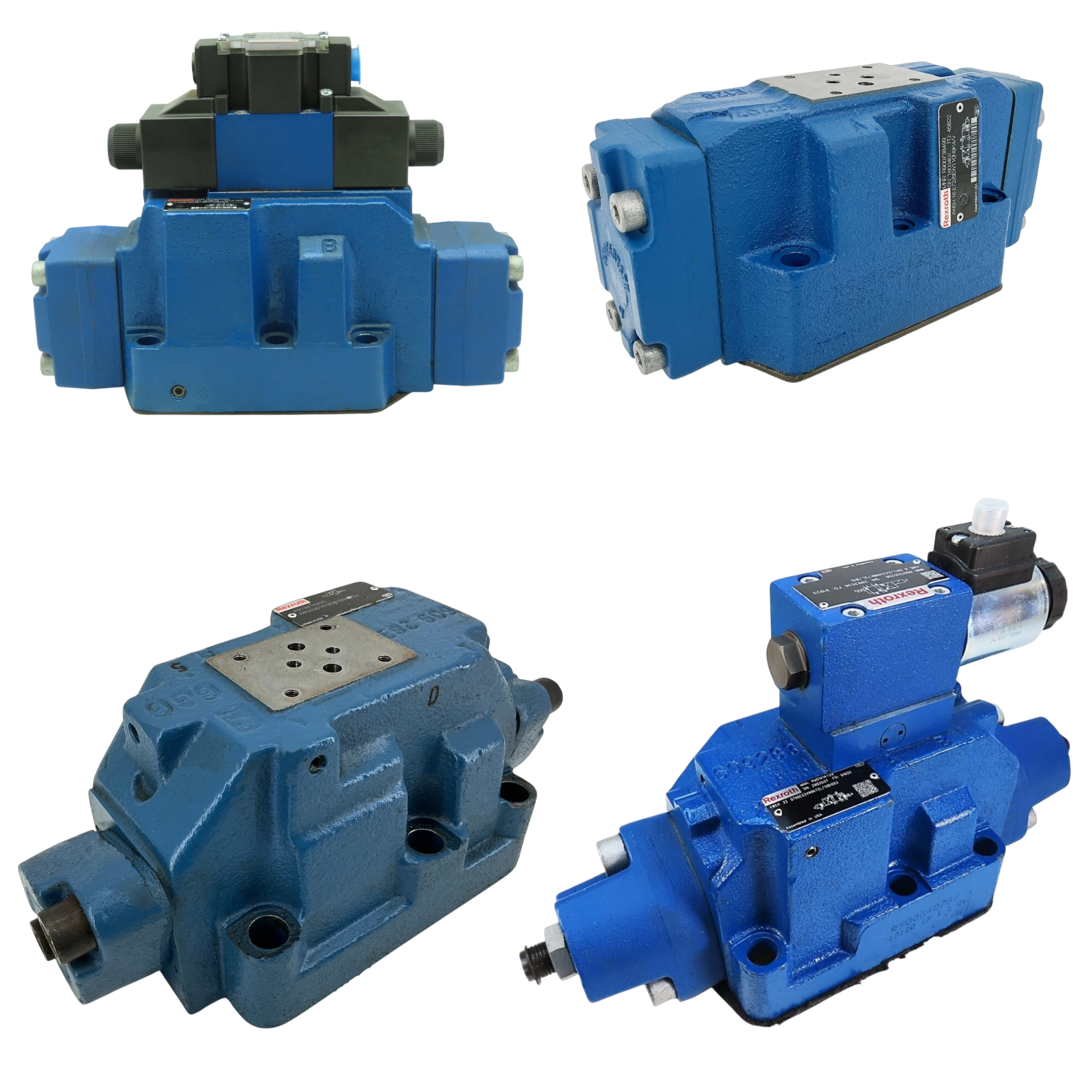

Bosch Rexroth | 4WH6GA5X5

4WH6GA5X/5

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The 4WH6GA5X/5 directional spool valve belongs to the WEH Directional Spool Valves series manufactured by Bosch Rexroth for hydraulic automation circuits requiring reliable flow path control. It is built with a nominal size of 6, allowing compact manifold mounting in machinery with limited space. The valve withstands a maximum operating pressure of 315 bar so it can handle high-pressure supply lines typical of industrial power units. A peak flow rate of 60 l/min supports medium capacity actuators without excessive pressure drop. The mounting interface follows ISO 4401-03-02-0-05 (D03) which standardizes the port layout for interchangeable sub-plate installations. Four M5 × 50 screws specified in ISO 4762 secure the body and maintain sealing integrity under load. The porting pattern corresponds to DIN 24340 Form A, ensuring compatibility with existing base plates designed to that pattern. A clamping length of 42 mm positions the spool accurately within the housing, contributing to consistent switching behavior. Pilot volume is 1.23 cm³, providing predictable response times when the pilot stage energizes.

Pilot control is effective from 6 bar to 200 bar, defining the permissible minimum and maximum pilot pressures for stable actuation. The tank port can tolerate up to 160 bar so back-pressure in return lines does not disturb valve operation. Switching frequency is limited to 2 Hz, allowing up to two directional changes per second without overheating or excessive wear. NBR seals are fitted to resist mineral hydraulic oils and maintain leakage control across the rated temperature span. The valve can be installed in any position which simplifies integration in densely packed power packs. Operation is permitted at ambient temperatures up to 80 °C, matching typical machine room conditions. Required fluid cleanliness is ISO 4406 20/18/15 so filtration must keep particle contamination below those codes for long service life. These characteristics support consistent directional control in presses, machine tools, and similar hydraulic systems.

Technical Specifications

Ambient Temp Max

80 C

Clamping Length

42 mm

Fluid Cleanliness Class

ISO 4406 20/18/15

Installation Position

Any

Max Flow

60 l/min

Max Operating Pressure

315 bar

Max Pilot Pressure

200 bar

Max Switching Frequency

2 Hz

Max Tank Port Pressure

160 bar

Min Pilot Pressure

6 bar

Mounting Interface

ISO 4401-03-02-0-05 (D03)

Mounting Screws

4×M5×50 (ISO 4762)

Nominal Size

6

Pilot Volume

1.23 cm³

Porting Pattern (din)

DIN 24340 Form A

Seal Material

NBR

Shipping & Payment Options