Bosch Rexroth | 4WEH22J7X6EW110N9ETS2K4B10

4WEH22J7X/6EW110N9ETS2K4/B10

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

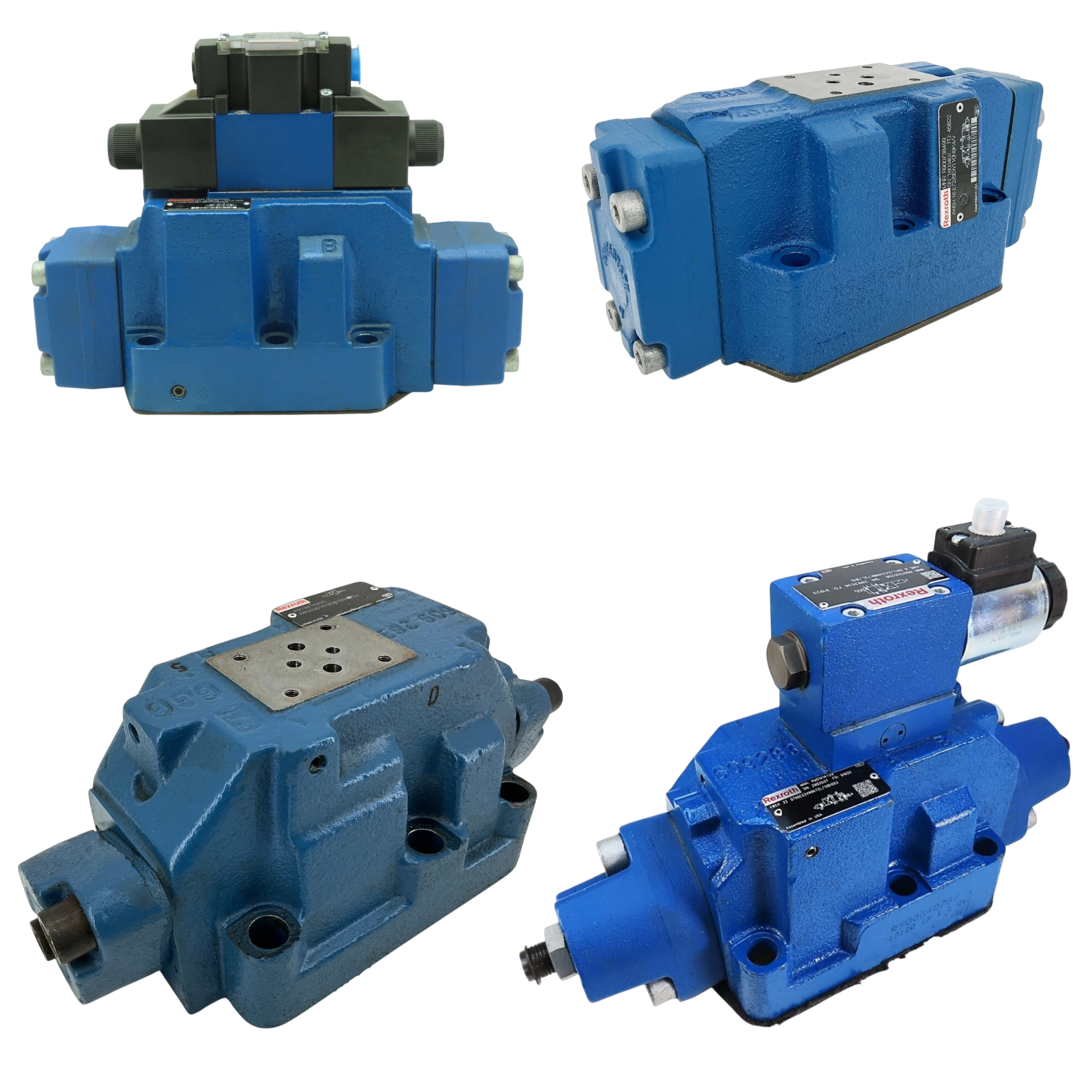

The 4WEH22J7X/6EW110N9ETS2K4/B10 directional spool valve is produced by Bosch Rexroth as part of the WEH Directional Spool Valves series. It directs hydraulic flow to actuators in automated machinery and does so with a nominal size of NG25 that matches medium-frame manifold blocks. The unit provides three spool positions so cylinders can extend, retract, or hold while circuits remain pressurized. A spring-centered design automatically returns the spool to the neutral position after actuation, simplifying fail-safe logic in mobile or stationary systems. Hydraulic supply passes through internal pilot oil channels, and return flow is also routed internally, removing the need for external pilot lines on the manifold. When the J-coded spool is selected, the valve handles a maximum flow rate of 450 l/min, giving ample capacity for high-demand cylinders. Working ports p, a, and b are rated for 280 bar, allowing the component to operate in high-pressure circuits without performance loss. Electrical actuation is provided via a DIN EN 175301-803 K4 connector, which offers standardized pin layout and quick coil replacement in field service.

The pilot stage tolerates pressures up to 210 bar, while port T withstands 250 bar to ensure safe drainage when backpressure builds in return lines. Reliable shifting is achieved once pilot pressure reaches at least 10.5 bar, so low-pressure standby pumps can still move the spool. The valve mounts on a subplate conforming to ISO 4401-08-08-0-05, and six M12 × 60 screws secure it firmly; each screw must be tightened to 100 Nm to preserve the sealing edge. Stroke timing can be tuned through a discharge control mechanism that adjusts switching time, allowing motion profiles to match cylinder loads. A built-in 1.0 mm throttle orifice limits pilot flow for smoother spool movement and reduced shock at changeover. These mechanical details complete the installation envelope and pressure boundaries required for dependable operation in hydraulic automation networks.

Technical Specifications

Centering Type

Spring-Centered

Electrical Connection

DIN EN 175301-803 (K4)

Max Flow (symbol J)

450 l/min

Max Operating Pressure (p,a,b)

280 bar

Max Pilot Pressure

210 bar

Max Pressure Port T

250 bar

Min Pilot Pressure (spring-centered)

10.5 bar

Mounting Interface

ISO 4401-08-08-0-05

Mounting Screws

6 × M12 × 60

Nominal Size

NG25

Pilot Oil Return

Internal

Pilot Oil Supply

Internal

Screw Tightening Torque

100 Nm

Spool Positions

3

Switching Time Adjustment

Discharge Control

Throttle Insert Orifice

1.0 mm

Shipping & Payment Options