Bosch Rexroth | 4WEH22J7X6EG24N9ES2K4B10-CSA

4WEH22J7X/6EG24N9ES2K4/B10 CSA

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

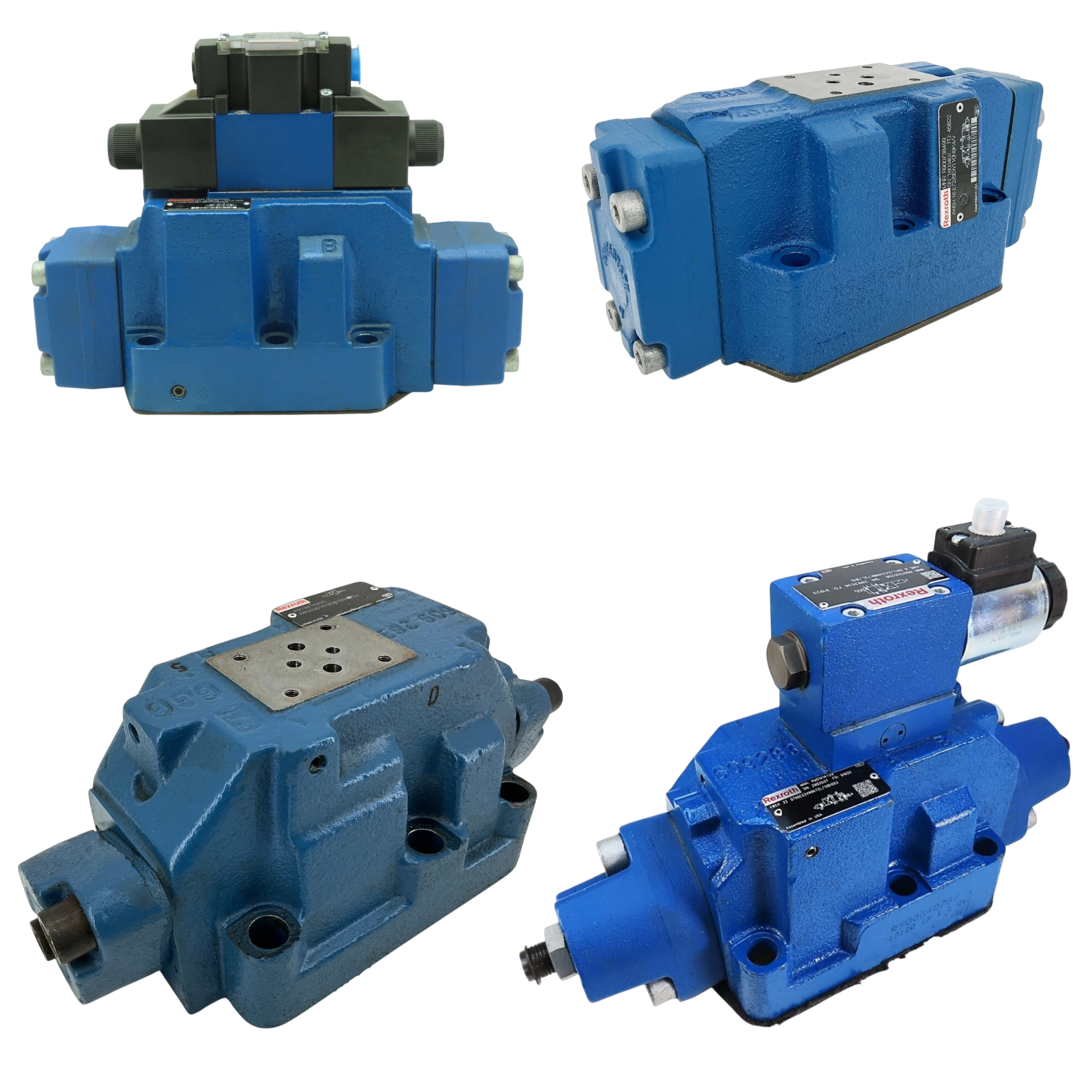

The 4WEH22J7X/6EG24N9ES2K4/B10 CSA directional valve is produced by Bosch Rexroth for the WEH Directional Spool Valves series and controls hydraulic actuators in automated systems. The valve features nominal size 25 so it can handle medium to large flow circuits. Three spool positions allow neutral, extend, and retract functions in four-way circuits. Under symbol J, the main ports conduct up to 450 l/min to satisfy high flow demands. The pressure-retaining parts tolerate 280 bar on ports P, A, and B, providing adequate capacity for high-pressure machines. Pilot supply can reach 210 bar, while the spring-centered design requires a minimum pilot pressure of 10.5 bar to shift reliably. When internally fed through channel X, pilot operation starts at 4.5 bar, reducing external supply needs. Pilot cavities store 7.64 cm³, defining the volume that must be pressurized for each transition. A 1.0 mm throttle orifice in position b10 meters pilot oil to damp spool movement.

The manifold interface follows ISO 4401-08-08-0-05, simplifying installation on standardized subplates. Six M12 × 60 mounting screws according to ISO 4762 secure the housing against hydraulic loads. Electrical actuation is connected with a DIN EN 175301-803 K4 plug so wiring is consistent with common industrial harnesses. Pilot oil returns through port y and may be back-pressured up to 210 bar without affecting function. Allowed surface coating thickness is limited to 100 µm to keep sealing edges free and maintain accurate fit in the manifold. Clean hydraulic fluid with a contamination level not worse than ISO 4406 20/18/15 is required to prevent accelerated wear. The mean time to dangerous failure is calculated at 100 years, supporting long maintenance intervals in safety-related circuits. Together, these construction features keep the valve durable and compatible with automated hydraulic control platforms.

Technical Specifications

Cleanliness Class

ISO 4406 (c) 20/18/15

Electrical Connection

DIN EN 175301-803 (K4)

Max Flow (symbol J)

450 l/min

Max Operating Pressure (p,a,b)

280 bar

Max Pilot Pressure

210 bar

Min P For X Internal

4.5 bar

Min Pilot Pressure (3-pos, Spring-centered)

10.5 bar

Mounting Screws

6 x M12 x 60 (ISO 4762)

Mttfd

100 years

Pilot Return Max Pressure (y, Dc)

210 bar

Pilot Volume (3-pos, Spring-centered)

7.64 cm3

Porting Pattern

ISO 4401-08-08-0-05

Size (ng)

25

Spool Positions

3

Surface Coating Max Thickness

100 µm

Throttle Orifice Diameter (b10)

1.0 mm

Shipping & Payment Options