Bosch Rexroth | 4WEH22G7X6EW110N9TK4

4WEH22G7X/6EW110N9TK4

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

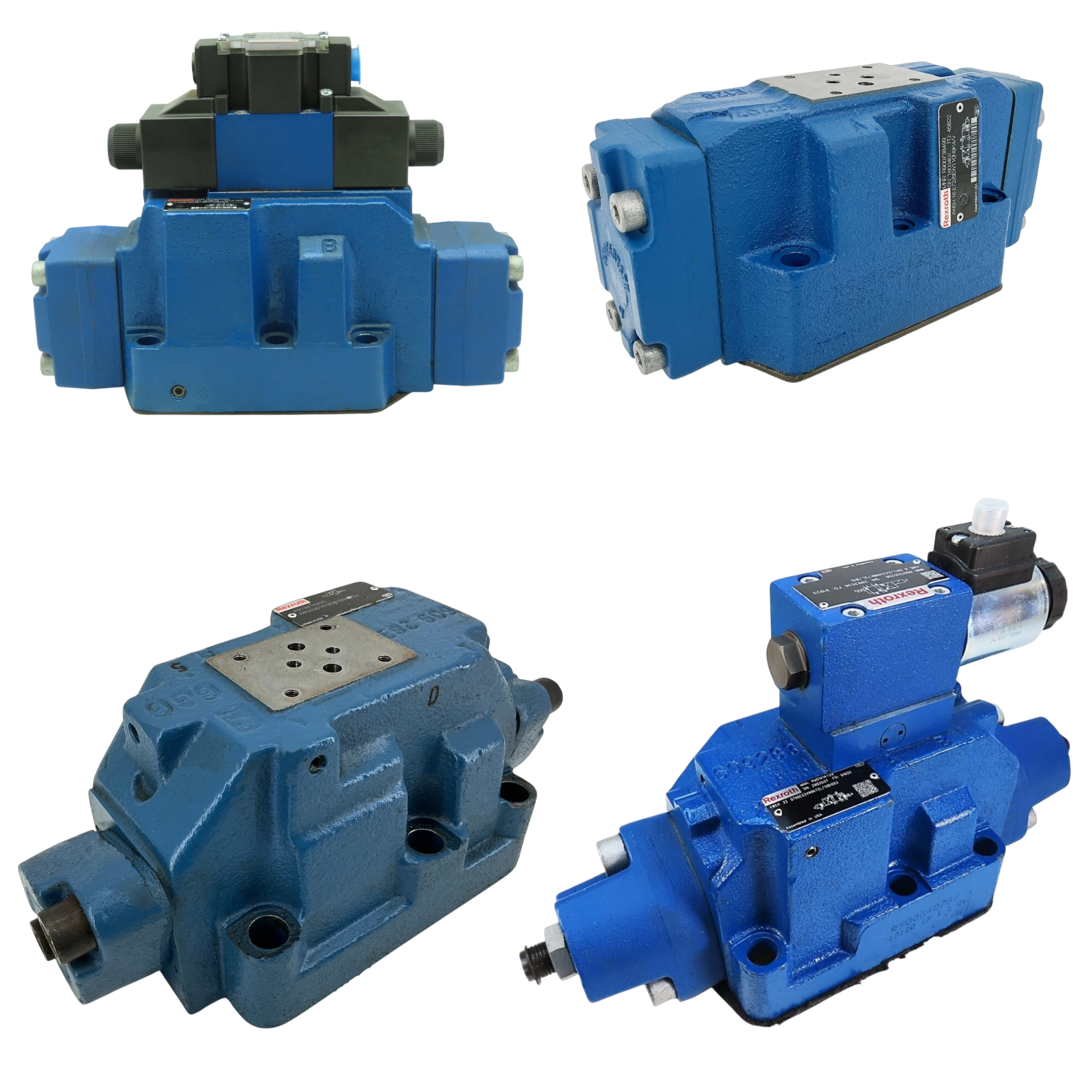

The 4WEH22G7X/6EW110N9TK4 directional spool valve is part of the WEH Directional Spool Valves series from Bosch Rexroth. Designed for hydraulic automation, it redirects pressurized oil to actuators under electro-hydraulic control. The NG25 size body carries a four-way flow path so cylinders or motors can extend and retract from a single housing. A spring-centered spool with three discrete positions, identified by symbol G, returns to neutral when pilot pressure is removed. The external pilot supply at port X energizes the shift, while internal return at port T drains pilot oil without extra piping. A minimum pilot pressure of 10.5 bar is required to move the spool, and a pilot limit of 210 bar prevents overstressing the control stage. When the hydraulic line reaches 210 bar the valve can pass up to 250 l/min, providing high flow capacity for large actuators.

The main stage withstands 280 bar at ports P, A, and B, allowing it to interface with high-pressure circuits in presses or injection machines. A porting pattern that matches ISO 4401-08-08-0-05 simplifies manifold mounting and ensures interchangeability with other NG25 components. The electrical interface uses a DIN EN 175301-803 K4 connector so standard cable harnesses can energize the solenoids. A concealed manual override, coded N9, lets maintenance staff shift the spool locally without disconnecting power. Oil cleanliness must meet ISO 4406 class 20/18/15 to protect the precision lands from abrasion. The design’s mean time to dangerous failure is calculated at 100 years, indicating low probability of functional loss over the service life. Together these characteristics establish reliable high-pressure flow direction control in automated hydraulic systems.

Technical Specifications

Actuation

Electro-Hydraulic

Cleanliness Class

ISO 4406 (c) 20/18/15

Electrical Connection

DIN EN 175301-803 (K4)

Flow Limit (symbol G @210 Bar)

250 l/min

Manual Override

Concealed (N9)

Max Operating Pressure (p,a,b)

280 bar

Max Pilot Pressure

210 bar

Min Pilot Pressure (3-pos Spring)

10.5 bar

Mttfd

100 Years

Pilot Return

Internal (T)

Pilot Supply

External (X)

Porting Pattern

ISO 4401-08-08-0-05

Size

NG25 (W.H 22)

Spool Positions

3 (Spring-Centered)

Spool Symbol

G

Way Configuration

4-Way

Shipping & Payment Options