Bosch Rexroth | 4WEH22G7X6EG12N9TDA

4WEH22G7X/6EG12N9TDA

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

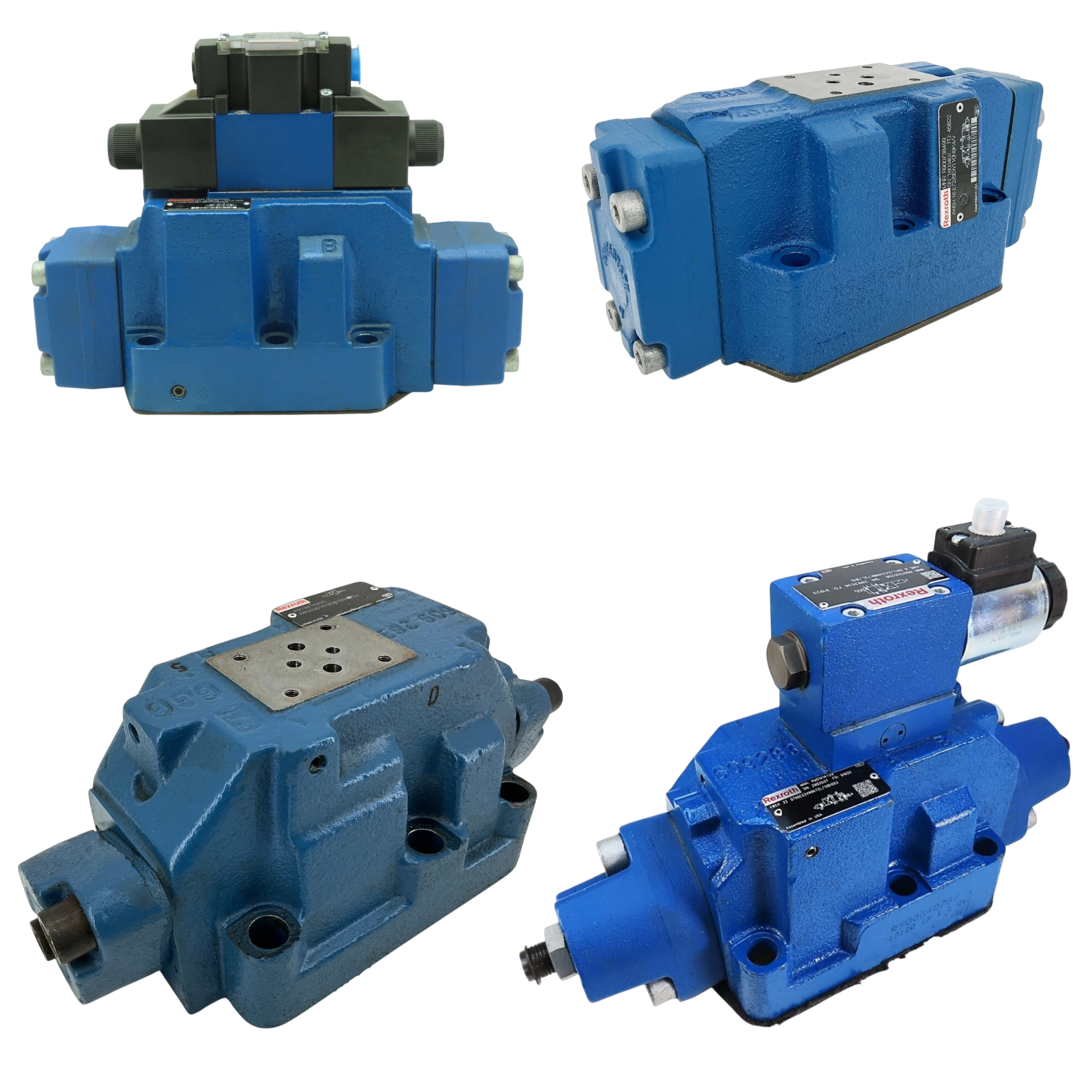

The 4WEH22G7X/6EG12N9TDA valve is produced by Bosch Rexroth and belongs to the WEH Directional Spool Valves series. It directs hydraulic flow in automated machinery and is identified as component series 7X, which defines its internal design revision. The NG25 (W.H 22) size establishes the mounting interface and flow capacity suited to medium-to-high flow circuits. A maximum operating pressure of 280 bar on ports P, A, and B supports high-pressure actuation tasks, while a maximum pilot pressure of 210 bar keeps the control stage within safe limits. For spring-centered, three-position operation, the pilot circuit must maintain at least 10.5 bar to shift the spool reliably. Hydraulic fluid may reach temperatures up to 80 °C without degrading performance, provided cleanliness is maintained at ISO 4406 20/18/15 to protect the precision fit surfaces. The unit connects to manifolds drilled to the ISO 4401-08-08-0-05 porting pattern, ensuring compatibility with standardized subplates across equipment lines.

Subplate mounting simplifies installation because the valve bolts directly to a manifold surface rather than requiring line plumbing. Six M12 × 60 screws secure the body, and each screw must be tightened to 100 Nm to achieve the specified clamping force. In this T version, pilot oil is supplied externally through port X, while the return path is routed internally to port T, reducing external hose connections on the drain side. A surface protection coating of up to 100 µm shields the housing from corrosion in humid plant environments. The assembly weighs 19.0 kg with two solenoids and a spring-centered spool, so lifting assistance may be needed during maintenance. Mean time to dangerous failure is calculated at 100 years, indicating high inherent reliability for safety-related control loops. Together, these mechanical details and service life figures make the valve suitable for continuous operation in automated hydraulic stations where fast directional changes and low downtime are required.

Technical Specifications

Cleanliness Class

ISO 4406 20/18/15

Component Series

7X

Hydraulic Fluid Temp Max

+80 °C

Max Operating Pressure (p,a,b)

280 bar

Max Pilot Pressure

210 bar

Min Pilot Pressure (3-pos Spring)

10.5 bar

Mounting Screws

M12 x 60 (6 pcs)

Mounting Type

Subplate Mounting

Mttfd (type Weh)

100 years

Pilot Oil Return

Internal via T (T Version)

Pilot Oil Supply

External via X (T Version)

Porting Pattern

ISO 4401-08-08-0-05

Screw Tightening Torque (m12)

100 Nm

Size

NG25 (W.H 22)

Surface Protection Coating

100 µm Max

Weight (two Solenoids, Spring-centered)

19.0 kg

Shipping & Payment Options