Bosch Rexroth | 4WEH22D7X6EW110N9EK4B10

4WEH22D7X/6EW110N9EK4/B10

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

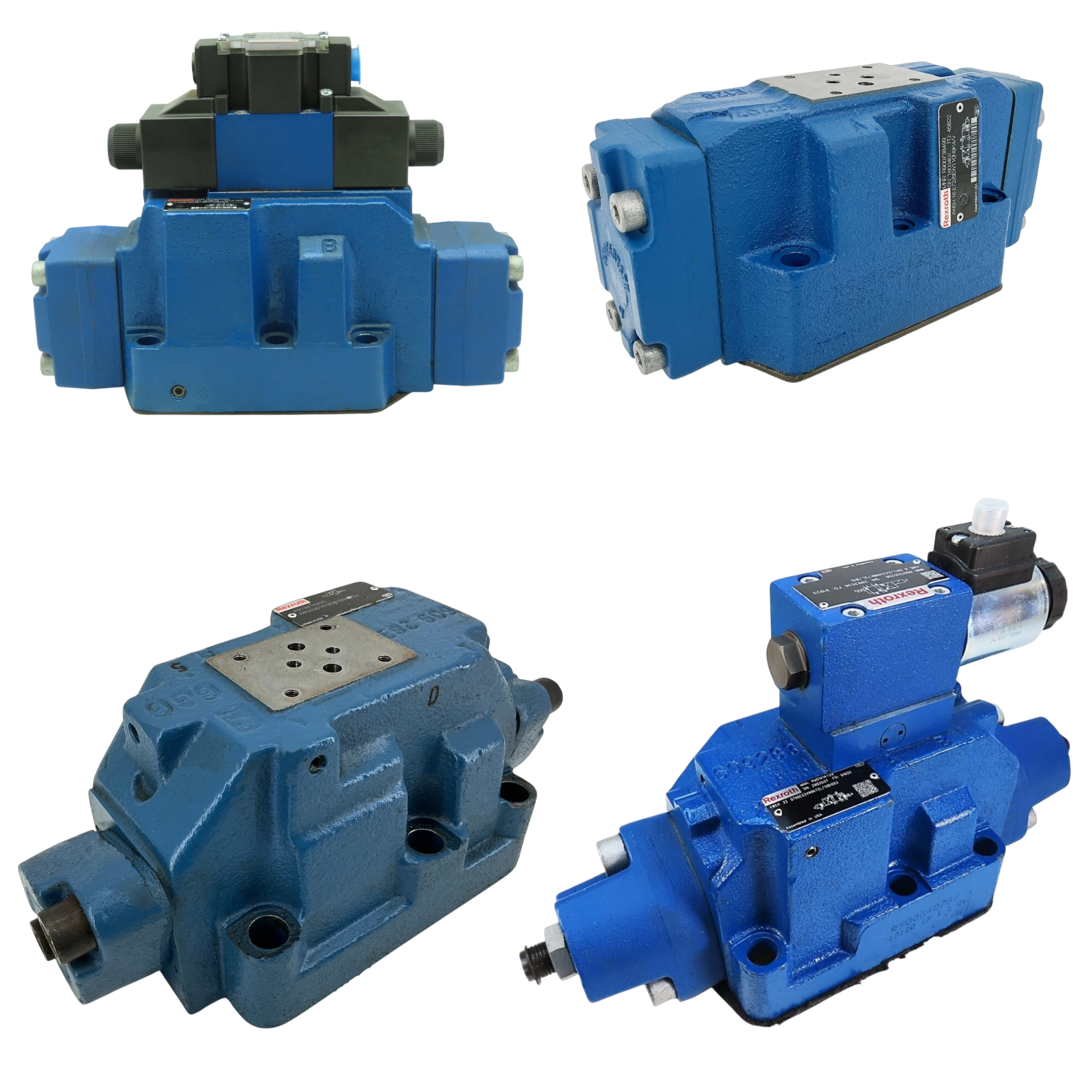

The 4WEH22D7X/6EW110N9EK4/B10 directional valve belongs to the WEH Directional Spool Valves series and is produced by Bosch Rexroth. As an electro-hydraulic unit it converts a small electrical pilot signal into hydraulic force so that the main spool can shift flow paths in automated circuits. The valve is built in nominal size NG25, a dimension that determines the flow capacity for medium-to-high flow applications. It provides two spool positions, governed by the D-pattern spool geometry, to route pressure from port P to either port A or B. Subplate mounting lets the body seat directly on a standardized base, while the ISO 4401-08-08-0-05 porting pattern aligns the pressure and tank passages without custom drilling. A DIN EN 175301-803 (K4) connector supplies the solenoid with voltage and simplifies field wiring. During operation the hydraulic channels can be loaded up to 280 bar at ports P, A, and B, allowing use in high-pressure work circuits. A 1.0 mm throttle insert is provided to meter pilot oil and damp switching impacts.

A separate pilot stage works within a maximum pressure of 210 bar and still shifts reliably when the inlet pressure reaches at least 11 bar, a figure relevant for spring-returned spool variants. System cleanliness must meet ISO 4406 (c) 20/18/15 so that contaminants do not score the precision-ground lands and lead to leakage. Particles above this limit would accelerate erosion and upset pressure balance, so filtration is mandatory. The external surfaces carry a corrosion-resistant coating up to 100 µm thick, extending service life in damp environments. Expected mean time to dangerous failure is 100 years, supporting long-term machine availability in safety-related installations. These durability measures combine with the stated pressure limits to keep the valve switching predictably over millions of cycles. Consistent pilot oil quality and surface protection therefore ensure accurate flow control throughout the product’s service life.

Technical Specifications

Actuation Type

Electro-Hydraulic

Cleanliness Class

ISO 4406 (c) 20/18/15

Electrical Connection

DIN EN 175301-803 (K4)

Max Operating Pressure (p, A, B)

280 bar

Max Pilot Pressure

210 bar

Min Pilot Pressure (2-spool, Spring End)

11 bar

Mounting Type

Subplate Mounting

Mttfd (weh)

100 years

Nominal Size

NG25

Porting Pattern

ISO 4401-08-08-0-05

Spool Positions

2

Spool Symbol

D

Surface Coating Thickness (max)

100 µm

Throttle Insert Diameter

1.0 mm

Shipping & Payment Options