Bosch Rexroth | 4WEH16J7X6EW110N9ETDK25LB10-CSA

4WEH16J7X/6EW110N9ETDK25L/B10 CSA

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

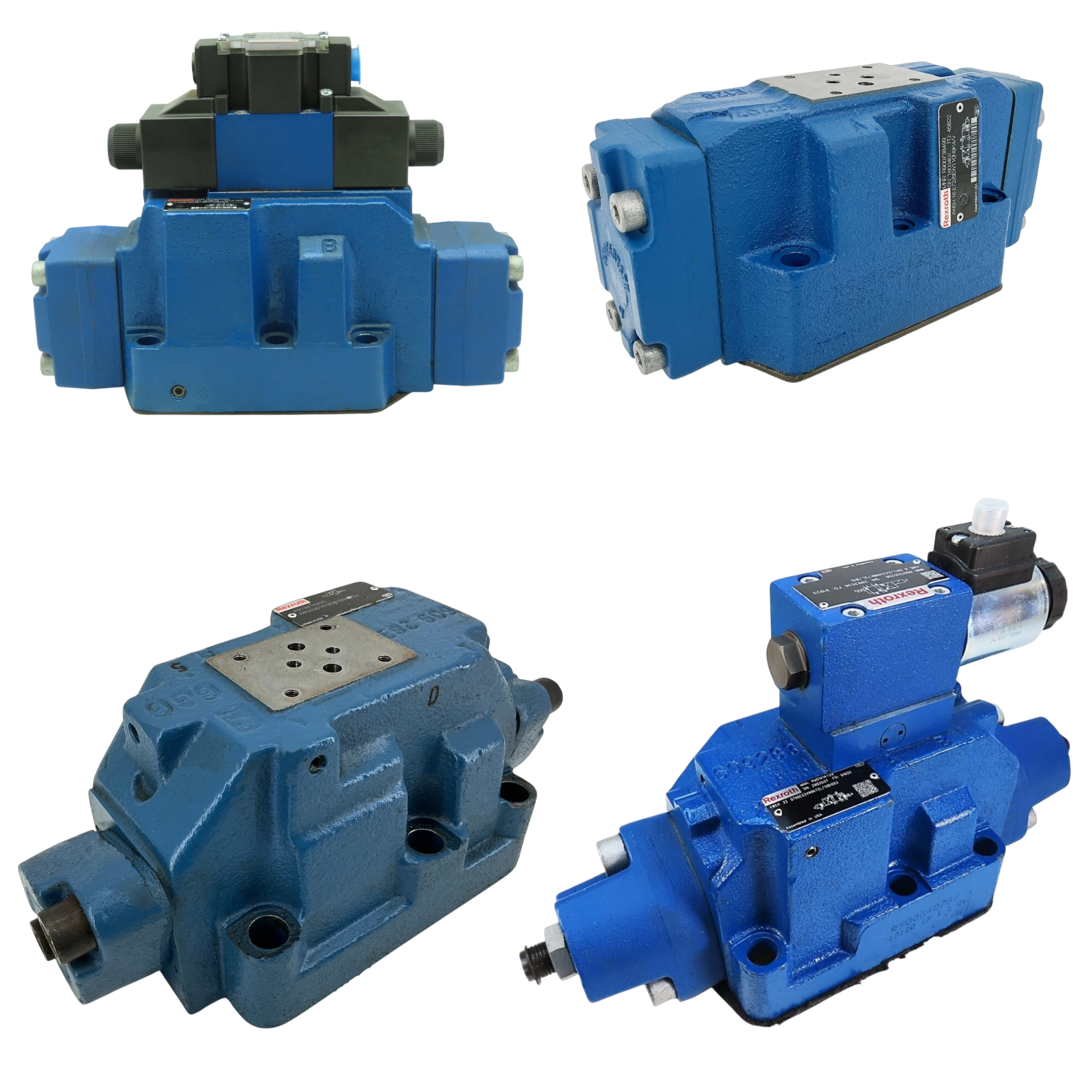

The 4WEH16J7X/6EW110N9ETDK25L/B10 CSA directional valve is part of the WEH Directional Spool Valves series manufactured by Bosch Rexroth. It guides hydraulic oil to the required actuator paths within automation circuits. The valve follows nominal size 16 (NG16), a dimension that establishes the passage area for the working ports and the resulting flow capability. Its ISO 4401-07-07-0-05 porting pattern aligns the body with standard subplates, and the chosen subplate mounting arrangement makes service replacement straightforward. Mounting screws must be tightened to 58 Nm so that mating surfaces stay sealed during pressure cycling. NBR sealing elements resist common mineral oils and maintain elasticity over temperature swings. A cleanliness class of ISO 4406 20/18/15 is required for the supplied fluid to prevent spool scoring. The machined contact surfaces are limited to a roughness of Rzmax 4, assuring uniform load on the elastomer seals. With two solenoids and a spring-centered spool the unit weighs 8.9 kg, which affects lifting and bracket selection.

Pilot control data define the actuation behavior of the same model. A maximum pilot pressure of 250 bar sets the upper force that the pilot stage may receive, while a minimum of 14 bar is needed to shift the spring-centered spool reliably. When a pilot flow of 35 l/min is available the valve reaches its shortest switching time, aided by a pilot volume of 5.72 cm³ that must be filled each cycle. Both the pilot oil supply and the pilot oil return are routed internally (ET), removing external lines and simplifying manifold design. A throttle insert with a 1.0 mm orifice, coded B10, adds damping to the control oil passage. The manual override can be used as long as tank pressure does not exceed 50 bar, preventing damage to the push pin. These limits combine to ensure predictable motion of cylinders and motors in automated equipment.

Technical Specifications

Cleanliness Class

ISO 4406 20/18/15

Contact Surface Roughness

Rzmax 4

Manual Override Tank Pressure Limit

50 bar

Maximum Pilot Pressure

250 bar

Minimum Pilot Pressure (spring-centered)

14 bar

Mounting Screw Tightening Torque

58 Nm

Mounting Type

Subplate Mounting

Nominal Size

16 (NG16)

Pilot Flow For Shortest Switching Time

35 l/min

Pilot Oil Return

Internal (ET)

Pilot Oil Supply

Internal (ET)

Pilot Volume (3-position Spring-centered)

5.72 cm3

Porting Pattern

ISO 4401-07-07-0-05

Seal Material

NBR

Throttle Insert Orifice

1.0 mm (B10)

Weight (two Solenoids, Spring-centered)

8.9 kg

Shipping & Payment Options