Bosch Rexroth | 4WEH16HD7XOF6EW110N9ES2DAL-CSA

4WEH16HD7X/OF6EW110N9ES2DAL CSA

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

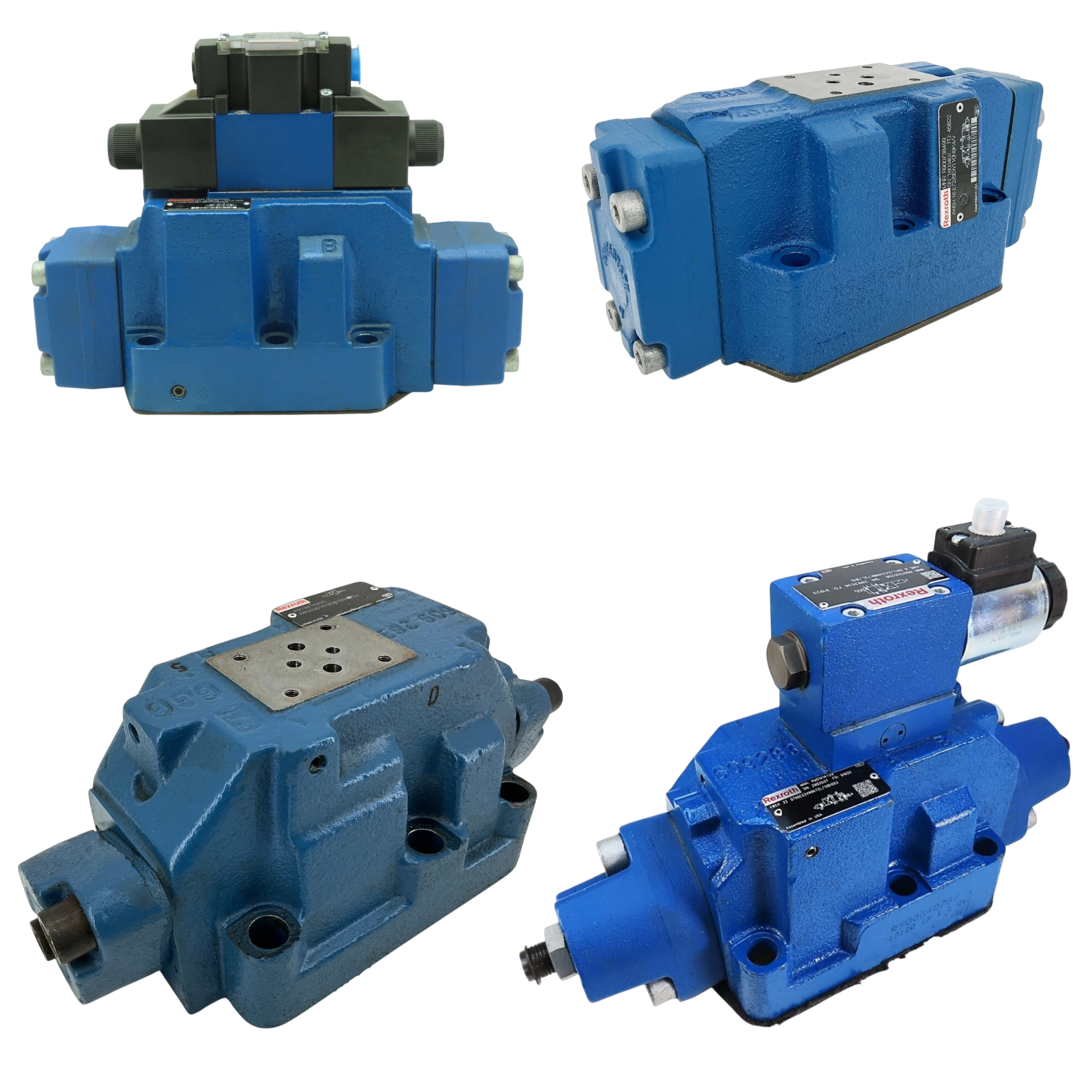

The 4WEH16HD7X/OF6EW110N9ES2DAL CSA directional spool valve is built by Bosch Rexroth within the WEH Directional Spool Valves series. It directs hydraulic flow to actuators in automated machinery. The valve uses nominal size 16 passages, allowing transfer rates suitable for mid-capacity circuits. A mounting interface defined as ISO 4401-07-07-0-05 lets it bolt directly to standard subplates without adapters. The hydraulic end can carry up to 300 l/min when configured with two spools, giving adequate volume for fast cylinder movement. Working ports p, a, and b accept operating pressures up to 350 bar, while the pilot stage tolerates supply pressures between 14 bar and 250 bar, so designers can choose conventional low or high pilot feeds. The pilot return port Y withstands 160 bar, preventing malfunction when back pressure rises. These limits outline the valve’s pressure and flow capabilities for demanding automation loops.

Fluid quality and environmental limits define service life for this model. It requires oil filtered to ISO 4406 cleanliness class 20/18/15 to protect internal lands from wear. Permissible kinematic viscosity ranges from 2.8 mm²/s to 500 mm²/s, enabling operation with light or heavy hydraulic fluids. Media temperature may lie between –20 °C and +80 °C, and ambient air may range from –20 °C to +50 °C, so the valve handles cold starts and moderate heat without derating. A concealed manual override designated N9 permits local actuation during commissioning or power loss while shielding the pushpin from accidental contact. Switching time can be tuned through discharge control S2, allowing optimization of spool transition speed for specific machine dynamics. Together these parameters define cleanliness, fluid condition, temperature margins, and control features required for reliable valve performance in automated hydraulic systems.

Technical Specifications

Fluid Cleanliness Class

ISO 4406 20/18/15

Manual Override

Concealed (N9)

Max Ambient Temperature (nbr)

+50 °C

Max Flow (2-spool, Hyd. End)

300 l/min

Max Fluid Temperature (nbr)

+80 °C

Max Kinematic Viscosity

500 mm2/s

Max Operating Pressure (p/a/b)

350 bar

Max Pilot Pressure

250 bar

Min Ambient Temperature (nbr)

-20 °C

Min Fluid Temperature (nbr)

-20 °C

Min Kinematic Viscosity

2.8 mm2/s

Min Pilot Pressure (2-spool, Hyd. End)

14 bar

Mounting Interface

ISO 4401-07-07-0-05

Nominal Size

16

Pilot Return Y Max Pressure (ac)

160 bar

Switching Time Adjustment

Discharge Control (S2)

Shipping & Payment Options