Bosch Rexroth | 4WEH16G7X6EW110N9TK4

4WEH16G7X/6EW110N9TK4

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

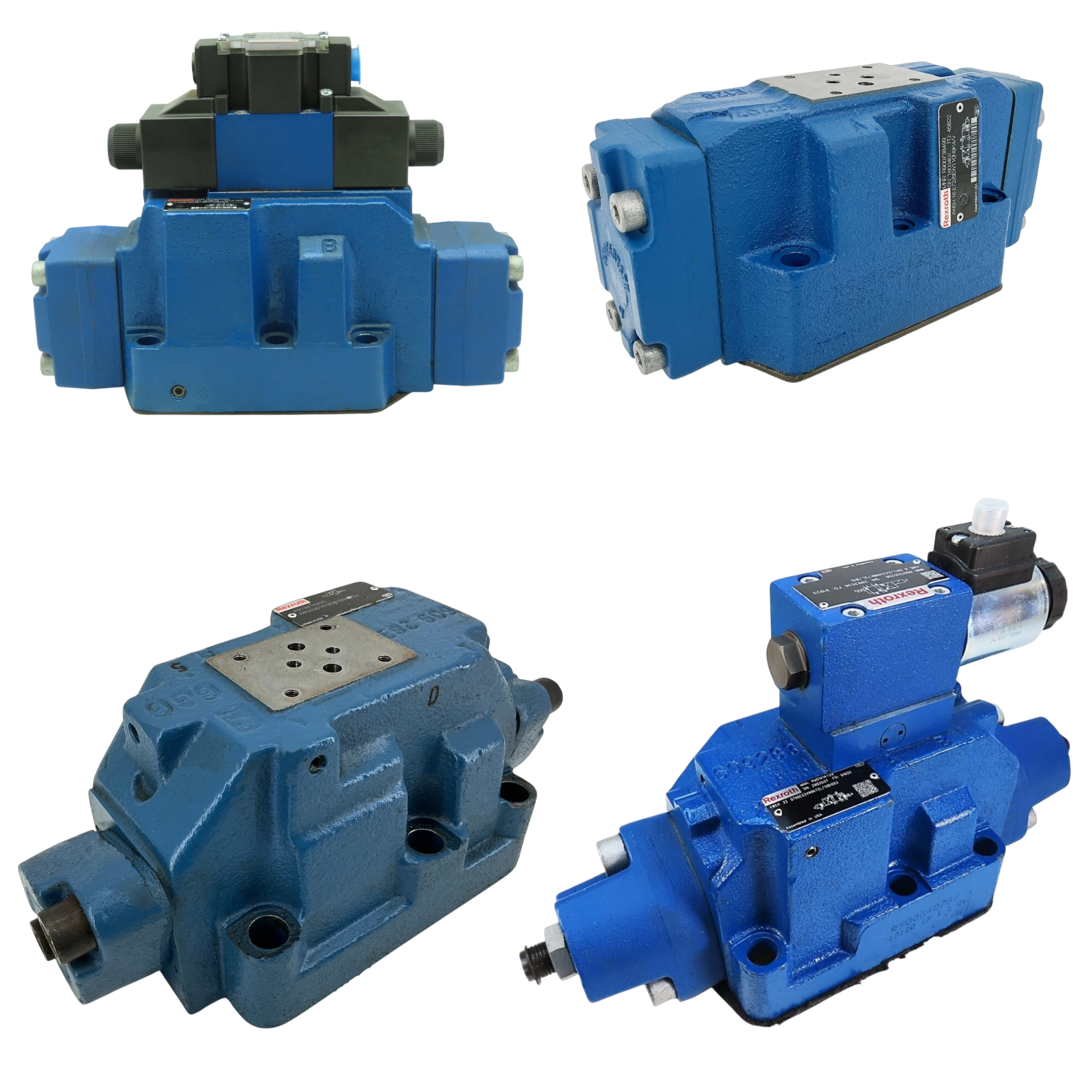

The 4WEH16G7X/6EW110N9TK4 directional valve belongs to the WEH Directional Spool Valves series from Bosch Rexroth. Designed for electro-hydraulic actuation, it directs flow in automated hydraulic circuits where rapid switching is required. The valve uses a 4-way configuration to control two service ports while its NG16 size matches medium-capacity manifolds. A spring return centers the main spool when the solenoids are de-energized, restoring the system to neutral without external assistance. The rated flow of 190 l/min at 350 bar for symbol G lets the valve handle substantial throughput in power units. Channels p, a, and b can withstand operating pressures up to 280 bar, giving headroom for high-pressure pumps. Pilot oil is supplied through external port X and is discharged internally through port T, simplifying piping on the manifold. Installation follows the ISO 4401-07-07-0-05 interface so the unit can replace other NG16 valves without block modifications.

Electrical hookup is provided by a DIN EN 175301-803 connector, enabling quick coil replacement during maintenance, and the standardized plug orientation permits pre-assembled harnesses to be reused across multiple valves. A fluid cleanliness level of 20/18/15 according to ISO 4406 must be maintained to protect the precision-ground spool from wear. The pilot stage tolerates pressures up to 250 bar, and external actuation requires a minimum of 14 bar when the valve is arranged in three-position mode. Four M10 x 60 screws secure the body to the subplate, and each fastener must be tightened to 58 Nm to preserve the gasket load throughout duty cycles. Functional safety is supported by a mean time to dangerous failure of 100 years, allowing the component to remain in service for decades before statistical replacement is needed. Together, these electrical, hydraulic, and mechanical limits define predictable behavior when the valve is embedded in automated machinery.

Technical Specifications

Actuation

Electro-Hydraulic

Cleanliness Class (iso 4406)

20/18/15

Electrical Connector

DIN EN 175301-803

Main Spool Return

Spring Return

Max Flow (symbol G, 350 Bar)

190 l/min

Max Operating Pressure (p,a,b)

280 bar

Max Pilot Pressure

250 bar

Min Pilot Pressure (x External, 3-pos)

14 bar

Mounting Interface

ISO 4401-07-07-0-05

Mounting Screws (ng16)

4 x M10 x 60

Mttfd

100 years

Pilot Oil Return

Internal (T)

Pilot Oil Supply

External (X)

Size

NG16

Tightening Torque (m10 Screws)

58 Nm

Way Version

4-Way

Shipping & Payment Options