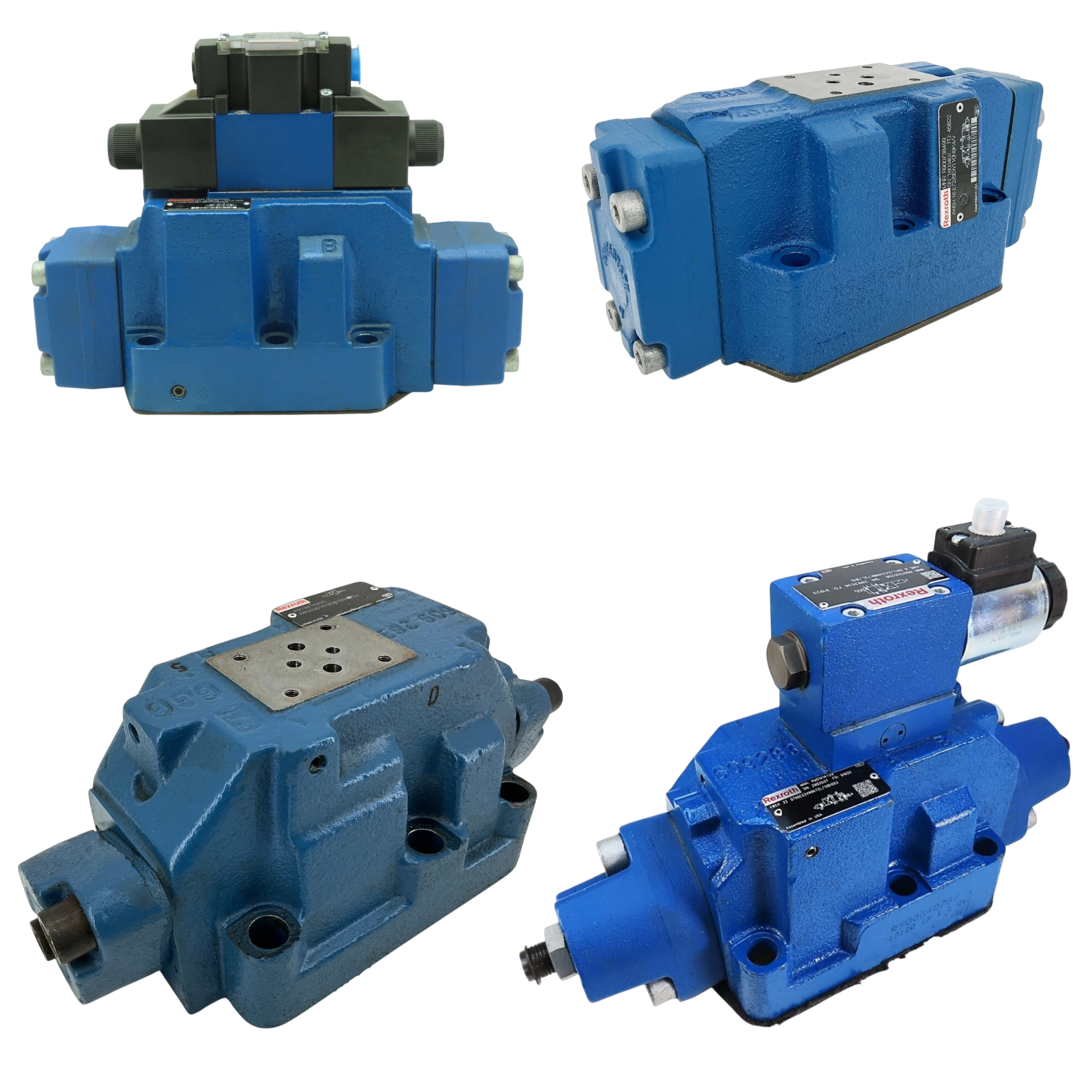

Bosch Rexroth | 4WEH10Y4X6EG24N9S2K4

4WEH10Y4X/6EG24N9S2K4

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The 4WEH10Y4X/6EG24N9S2K4 valve is produced by Bosch Rexroth for the WEH Directional Spool Valves series. It directs actuator flow in electro-hydraulic equipment where external pilot oil is acceptable. The nominal size NG10 establishes a port geometry that supports common mid-range flow rates, while the design provides two spool positions so cylinders can be extended or retracted under electrical command. External pilot oil enters through port X, and external return is routed through port Y to isolate control pressure from the main flow path. The unit maintains line pressure in ports p, a, and b up to 280 bar so it suits high-pressure industrial presses. Spool movement begins once a pilot pressure of 10 bar is present and can rise to 250 bar without overloading the pilot stage. A spring returns the spool to its end position when the solenoid is de-energized, ensuring a defined fail-safe state.

Installation follows the ISO 4401-05-05-0-05 mounting interface so the valve bolts directly onto standard NG10 subplates without additional adapters. The solenoid coil is energized with 24 V DC and terminates through a DIN EN 175301-803 plug coded K4, allowing quick connection in cabinet wiring harnesses. Switching speed can be fine-tuned by the discharge control feature marked S2, letting designers match response time to system dynamics. A concealed manual override designated N9 permits local actuation during commissioning while protecting the push pin from accidental contact. Port T withstands back-pressure up to 280 bar, supporting circuits that experience high shock loads or restricted tank lines. Hydraulic cleanliness must be maintained to ISO 4406 (c) 20/18/15 to prevent spool scoring and leakage. The predicted mean time to dangerous failure is 100 years, giving long service intervals in safety-related machinery.

Technical Specifications

Cleanliness Class

ISO 4406 (c) 20/18/15

Control Spool Return

Spring End Position

Electrical Connection

DIN EN 175301-803 (K4)

Manual Override

Concealed (N9)

Max Operating Pressure (p,a,b)

280 bar

Max Pilot Pressure

250 bar

Max Pressure Port T

280 bar

Min Pilot Pressure

10 bar

Mounting Interface

ISO 4401-05-05-0-05

Mttfd

100 years

Nominal Size

NG10

Pilot Oil Return

External (Y)

Pilot Oil Supply

External (X)

Spool Positions

2

Supply Voltage

24 V DC

Switching Time Adjustment

Discharge Control (S2)

Shipping & Payment Options