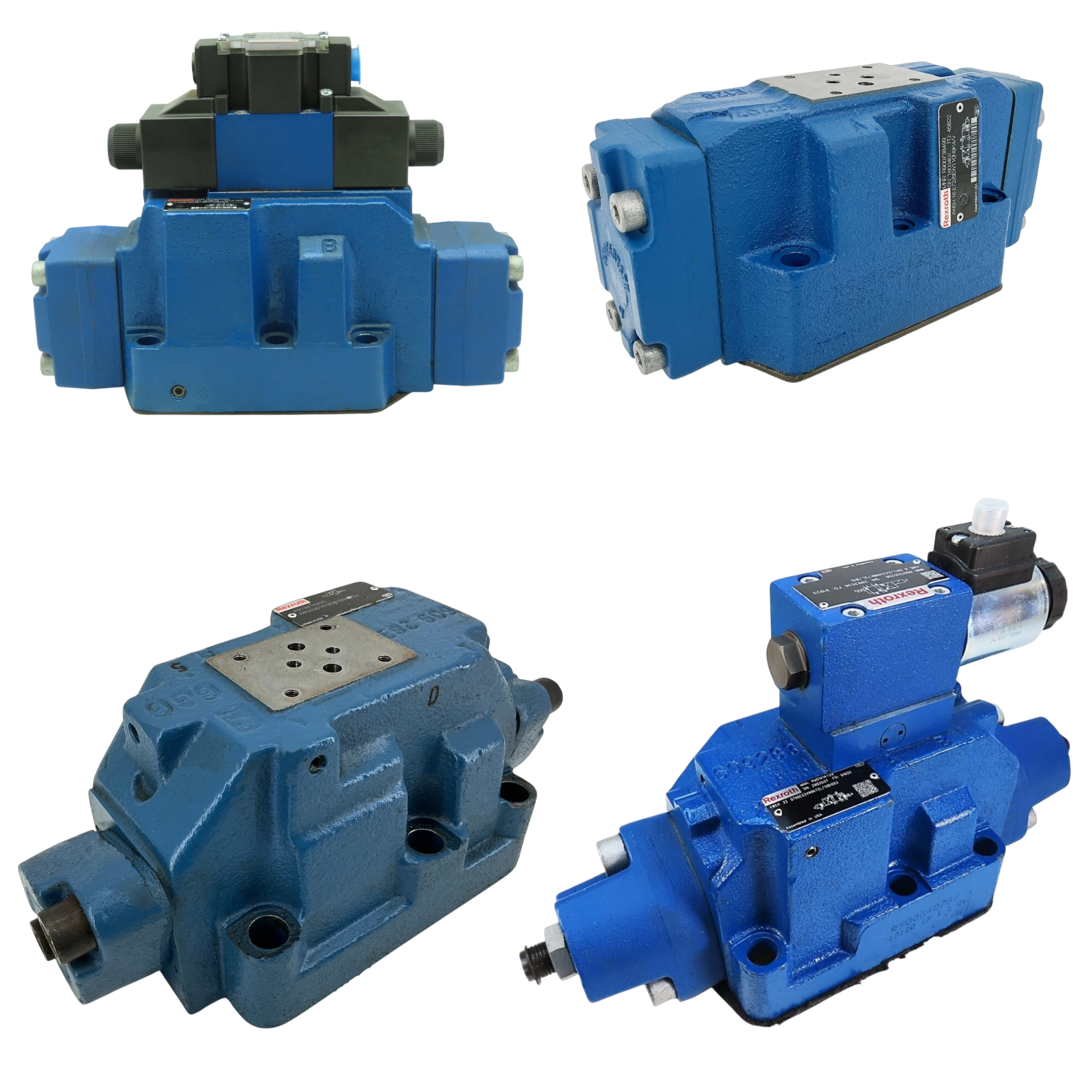

Bosch Rexroth | 4WEH10H4X6EW110N9TK4

4WEH10H4X/6EW110N9TK4

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The 4WEH10H4X/6EW110N9TK4 directional valve is part of the WEH Directional Spool Valves series from Bosch Rexroth and directs flow in automated hydraulic circuits. It uses electro-hydraulic actuation so a solenoid-driven pilot stage shifts the main spool with minimal manual effort. The component follows a 4-way configuration, providing two controlled flow paths for typical cylinder or motor circuits. Nominal size NG10 matches ISO size coding and defines the port dimensions for medium-flow machinery manifolds. It installs on a subplate with the ISO 4401-05-05-0-05 interface, ensuring interchangeability with common CETOP 5 patterns. The pilot oil is supplied externally through port X, allowing designers to choose a pressure source independent of the main line. Return flow from the pilot stage is routed internally to port T, removing the need for a dedicated drain line. A hydraulic spring chamber returns the control spool to its rest position, providing fail-safe centering when pilot pressure is removed. A pilot flow of 35 l/min achieves the shortest switching time and supports rapid machine cycles.

Maximum operating pressure of 280 bar on ports P, A, and B allows the valve to control high-pressure industrial circuits such as metal forming presses. The pilot stage tolerates up to 250 bar, so pilot lines can share pressure with the main supply without exceeding design limits or compromising response. An electrical plug coded to DIN EN 175301-803 K4 connects the solenoid, giving a standardized interface for cabinet wiring and quick field replacement. Acceptable hydraulic fluid temperatures from -20 to +80 °C when using NBR seals enable year-round outdoor service in cold storage or hot-plant environments. The design works with viscosities between 2.8 and 500 mm²/s, covering common mineral oils and certain synthetic fluids used in presses and mobile equipment. Fluid cleanliness must meet ISO 4406 class 20/18/15 to protect precision spool lands from wear and sticking over long maintenance intervals. Mean time to dangerous failure is rated at 100 years, indicating a very low probability of safety-critical malfunction during the expected equipment lifetime.

Technical Specifications

Actuation

Electro-Hydraulic

Cleanliness Class

ISO 4406 (c) 20/18/15

Control Spool Return

Hydraulic

Electrical Connection

DIN EN 175301-803 (K4)

Hydraulic Fluid Temp

−20…+80 °C (NBR)

Max Operating Pressure (p,a,b)

280 bar

Max Pilot Pressure

250 bar

Mounting Interface

ISO 4401-05-05-0-05

Mttfd

100 Years

Pilot Flow For Shortest Switching Time

35 l/min

Pilot Oil Return

Internal (T)

Pilot Oil Supply

External (X)

Size

NG10

Viscosity Range

2.8…500 mm²/s

Way Type

4-Way

Shipping & Payment Options