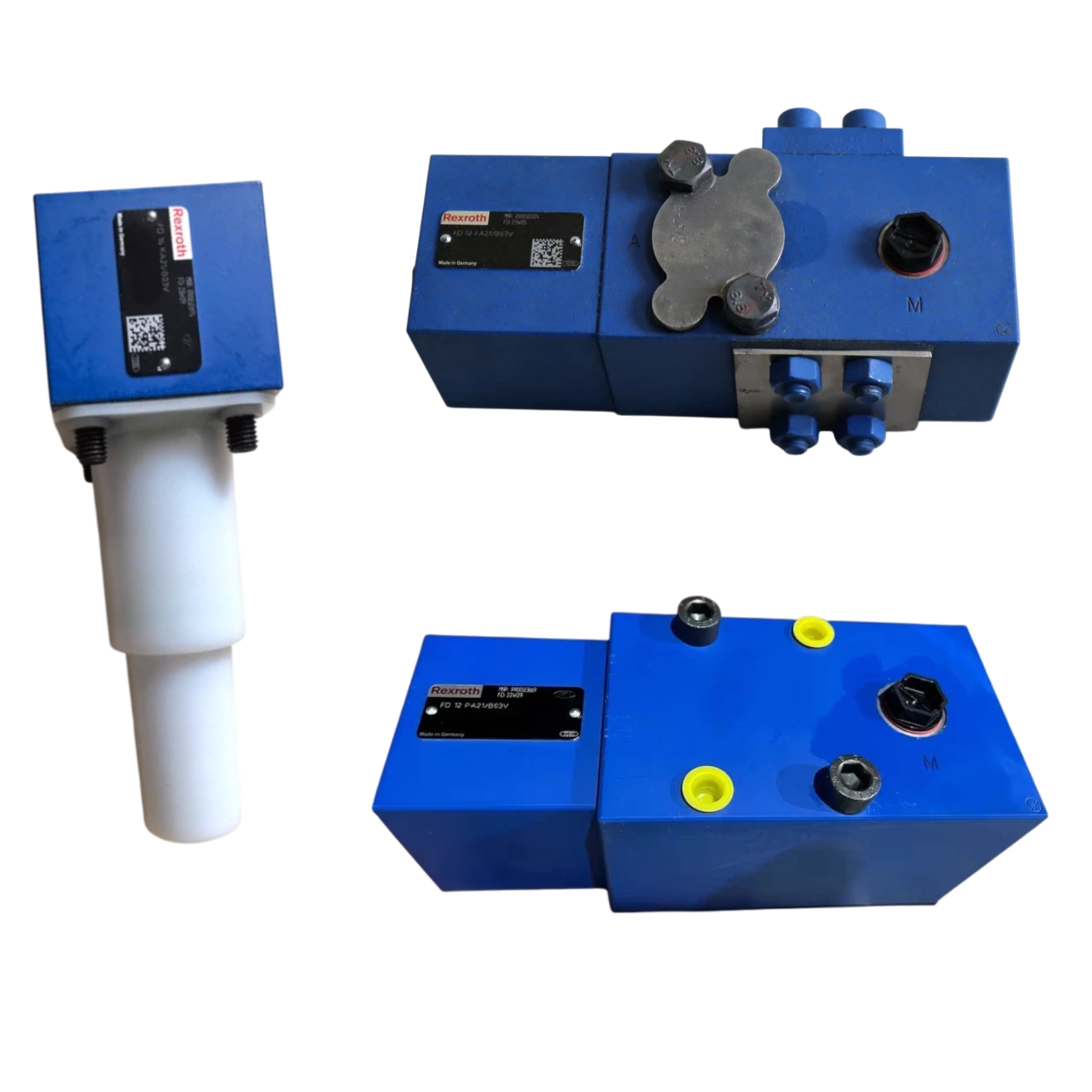

Bosch Rexroth | FD25PA2XB06V

FD25PA2X/B06V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The FD25PA2X/B06V valve is manufactured by Bosch Rexroth for the FD Check Valves series and serves as a blocking element in hydraulic automation where reverse flow must be prevented. It follows the ISO 5781-08-10-0-00 porting pattern, so it aligns with subplates drilled to that code. Port A can withstand pressures up to 350 bar while port B is rated for 420 bar, enabling use in high-pressure supply and return lines. The valve accommodates a maximum flow of 320 l/min, allowing medium-capacity circuits to operate without excessive pressure drop. A cracking pressure of 2 bar from A to B keeps the poppet seated until a defined upstream load is reached. When pilot pressure is introduced at port X, the pre-opening pressure of 20 bar and a pre-opening area ratio of 1:20 assist in controlled decompression before full opening. An internal orifice of 0.6 mm meters this pilot oil, ensuring gradual actuation and damped pressure transients.

Installation uses four M10 × 120 fixing screws tightened to 75 Nm, securing the valve to the manifold block. The control or measuring port is threaded G 1/4, providing a common point for pressure gauges or pilot lines. Flow enters or exits through 22 mm passage diameters at ports A and B, matching standard bore sizes in size 08 cavities. Sealing against the subplate is handled by an FKM material set, and each port uses an O-ring measuring 29.82 × 2.62 mm to prevent external leakage. The hydraulic fluid must be mineral oil graded HL or HLP, ensuring compatibility with the internal elastomers and wear surfaces. System cleanliness should meet ISO 4406 class 20/18/15 so the seat and pilot passages remain free of contamination. These mounting, sealing, and fluid requirements enable consistent behavior through the G 1/4 pilot interface and maintain the rated performance over the valve’s service life.

Technical Specifications

Cleanliness Level

ISO 4406 20/18/15

Control/measuring Port Thread

G 1/4

Cracking Pressure A To B

2 bar

Fixing Screw Torque

75 Nm

Fixing Screws

4x M10 × 120

Hydraulic Fluid

Mineral Oil (HL, HLP)

Maximum Flow

320 l/min

O-ring Size

29.82 × 2.62

Orifice Diameter

0.6 mm

Port A/b Diameter

22 mm

Port A/x Max Pressure

350 bar

Port B Max Pressure

420 bar

Porting Pattern

ISO 5781-08-10-0-00

Pre-opening Area Ratio

1:20

Pre-opening Pressure At X

20 bar

Sealing Material

FKM

Shipping & Payment Options