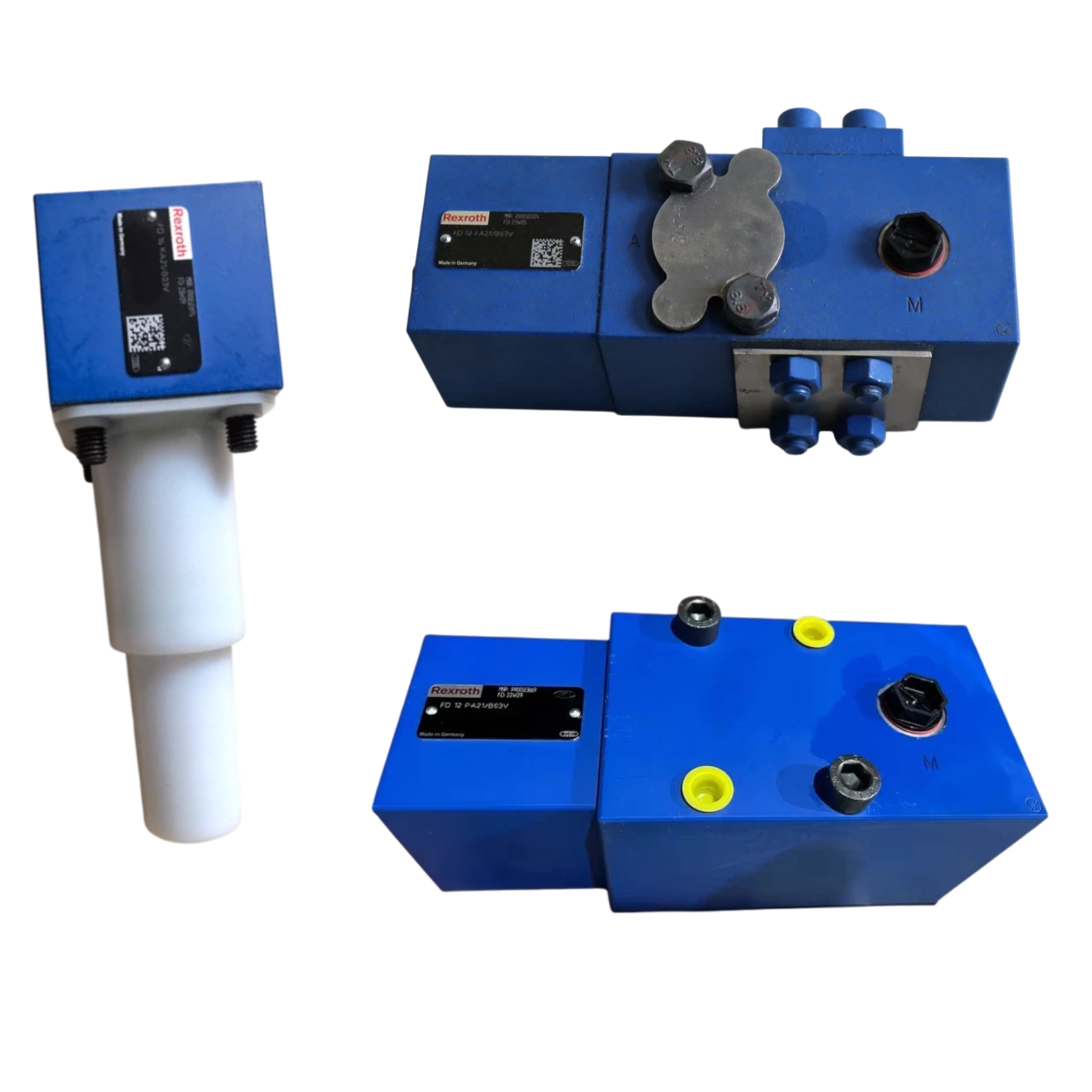

Bosch Rexroth | FD12PA2XB03V12

FD12PA2X/B03V12

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The FD12PA2X/B03V12 check valve is manufactured by Bosch Rexroth for the FD Check Valves series and is intended to permit controlled flow in hydraulic automation circuits. It is built in nominal size 12, a size that balances compact dimensions with adequate flow capacity for medium power systems. Sub-plate mounting simplifies replacement and minimizes pipework in manifold assemblies. The porting pattern corresponds to ISO 5781-06-07-0-00 so it aligns with standardized base plates used in industrial manifolds. Four M10 × 100 fixing screws secure the body to the sub-plate, and each screw requires a tightening torque of 75 Nm to maintain seal integrity under pressure. Port A withstands operating pressures up to 350 bar, allowing it to handle high-pressure pump lines, while port B is rated for 420 bar to accommodate load-induced peaks. Despite the pressure capability the valve weighs 9 kg, which eases manual installation during maintenance.

The valve incorporates a control-to-load area ratio of 1:20 so a small pilot pressure can overcome the internal spring and seat forces to open it against load pressure. Flow from port A to port B is limited by a cracking pressure of 2 bar, ensuring the line remains closed until pump pressure rises above standby levels. In the reverse direction, initial opening from port B to port A occurs at 20 bar, a higher threshold that prevents backflow during load holding. Once open the unit passes up to 80 l/min, supporting moderate actuator speeds without creating excessive pressure loss. A 0.3 mm orifice is integrated to control pilot flow and damp switching shocks. Mineral oil of the HL or HLP classes is the approved hydraulic fluid so standard system oils can be used without compatibility issues. To preserve sealing surfaces the supplied fluid must meet an ISO 4406 cleanliness level of 20/18/15, which limits particulate wear. FKM seals provide resistance to high temperature and aggressive oil additives, maintaining leak-free service over long duty cycles.

Technical Specifications

Area Ratio (control:load)

1:20

Cleanliness Level (iso 4406)

20/18/15

Cracking Pressure A→b

2 bar

Fixing Screws

4 × M10 × 100

Hydraulic Fluid

Mineral Oil (HL, HLP)

Max Flow (port A/b)

80 l/min

Max Operating Pressure (port A)

350 bar

Max Operating Pressure (port B)

420 bar

Mounting Type

Sub-Plate

Nominal Size

12

Opening Pressure B→a (start)

20 bar

Orifice Diameter

0.3 mm

Porting Pattern

ISO 5781-06-07-0-00

Screw Tightening Torque

75 Nm

Sealing Material

FKM

Weight

9 kg

Shipping & Payment Options