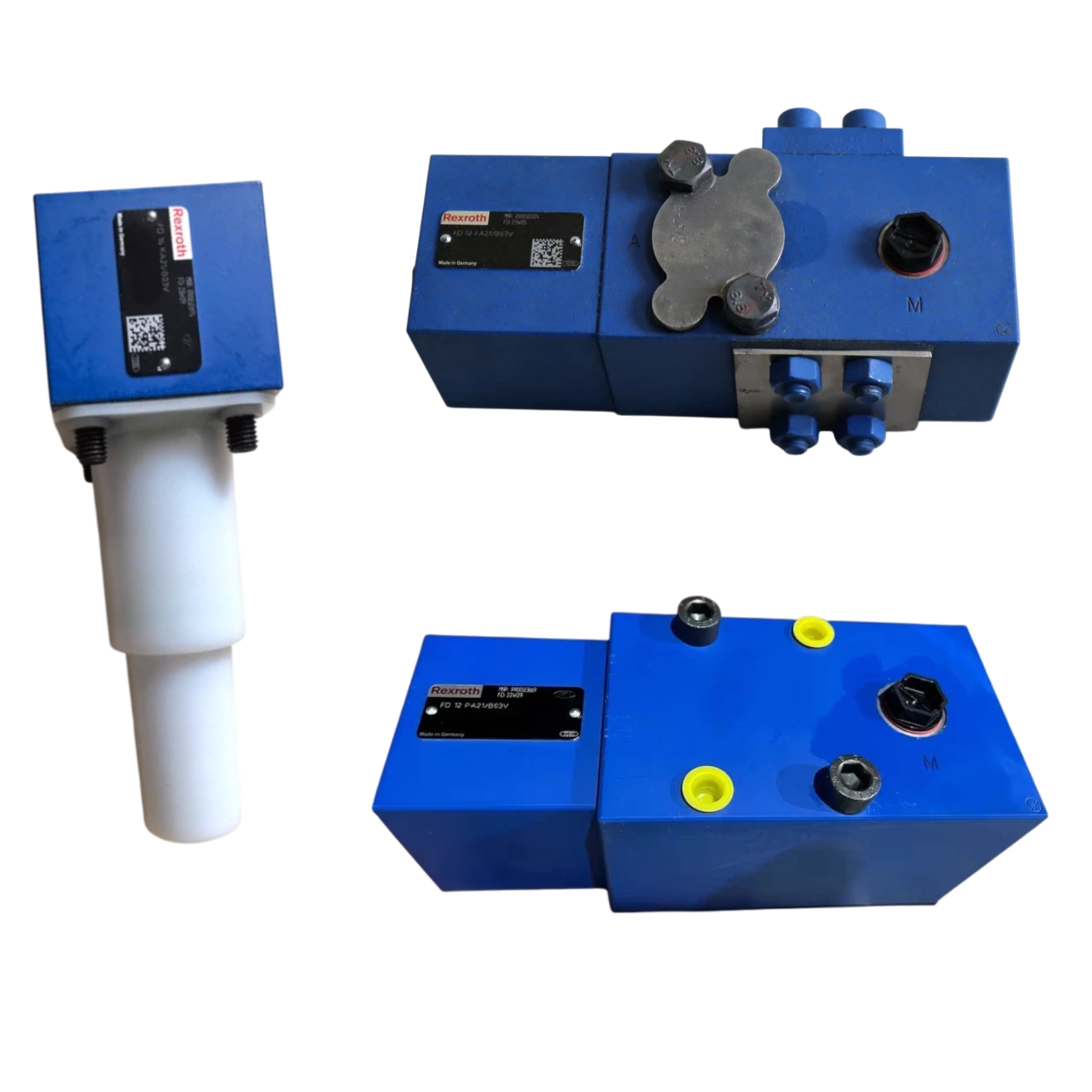

Bosch Rexroth | FD12FA2XB06V

FD12FA2X/B06V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The FD12FA2X/B06V check valve belongs to the FD Check Valves series and is produced by Bosch Rexroth for hydraulic automation circuits. It permits unidirectional flow because the free-flow path runs from port A to port B, preventing reverse leakage during normal operation. A cracking pressure of 2 bar opens the poppet in the A→B direction, so the actuator sees minimal pressure loss when the circuit starts. Maximum flow through ports A and B is 80 l/min, enabling moderate-capacity lines to move oil without cavitation. The port-side pressure limit for A and auxiliary X connections is 350 bar, providing adequate headroom for standard industrial power units. Mineral oil grades HL or HLP are the specified hydraulic media, ensuring compatibility with seals and internal finishes. A 0.6 mm damping orifice smooths dynamic pressure spikes, and a control-to-load area ratio of 1:20 allows small pilot signals at port X to influence poppet movement. Both the control port and the main pipe interfaces use G1/4 threads in accordance with ISO 228/1, making connection with standard BSP fittings straightforward.

Reverse flow characteristics are defined by a 20 bar pre-opening pressure in the B→A direction, so the valve can be piloted open when back-pressure relief is required. Port B tolerates system pressures up to 420 bar, allowing the component to sit directly on high-pressure lines downstream of pumps or cylinders. A dedicated measuring port with a G1/4 thread lets technicians monitor line pressure without additional tees. Acceptable fluid cleanliness is 20/18/15 per ISO 4406, which maintains poppet sealing and extends service intervals. The sealing interface relies on a 25 × 3.5 mm O-ring made from FKM to resist mineral oil and elevated temperatures. Overall mass is 7 kg, so mounting brackets must handle that static load. These attributes support precise check or directional-control functions in compact manifolds and protect downstream equipment from pressure surges.

Technical Specifications

Control Port Thread

G1/4

Control:load Area Ratio

1:20

Cracking Pressure (a→b)

2 bar

Fluid Cleanliness (iso 4406)

20/18/15

Free-flow Direction

A→B

Hydraulic Fluid Type

Mineral oil (HL, HLP)

Max Flow (ports A,b)

80 l/min

Max Pressure (port B)

420 bar

Max Pressure (ports A,x)

350 bar

Measuring Port Thread

G1/4

O-ring Size

25 × 3.5 mm

Orifice Diameter

0.6 mm

Pipe Thread Standard

ISO 228/1

Pre-opening Pressure (b→a)

20 bar

Sealing Material

FKM

Weight

7 kg

Shipping & Payment Options