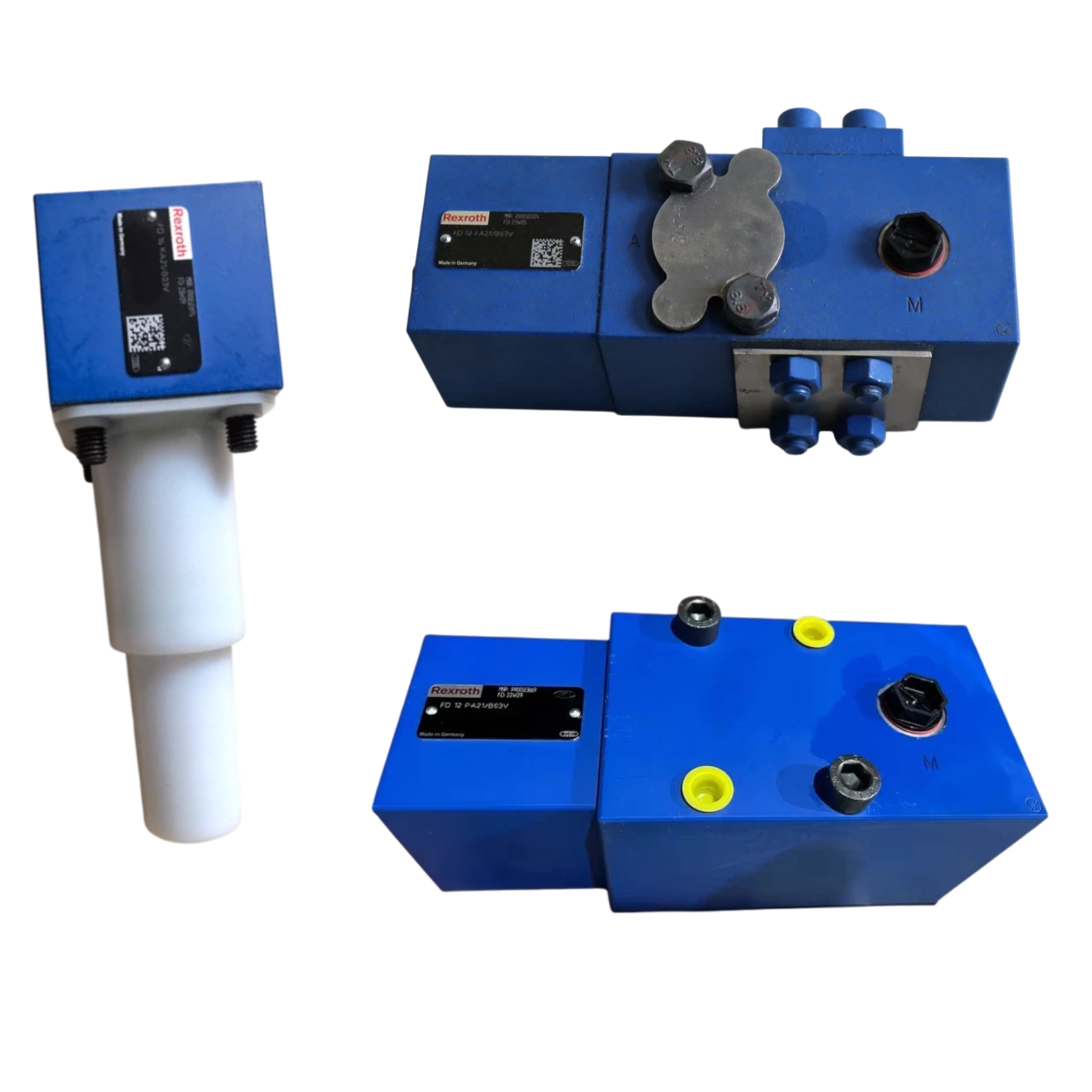

Bosch Rexroth | FD12FA2XB03V

FD12FA2X/B03V

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The FD12FA2X/B03V check valve belongs to the FD Check Valves series and is manufactured by Bosch Rexroth to permit one-directional flow in hydraulic automation loops. Its nominal size 12 defines the passage area and makes it suitable for medium-capacity circuits. An SAE flange connection simplifies installation on manifold blocks and resists leakage under dynamic loads. A dedicated G1/4 control or measuring port lets designers attach test gauges or pilot lines without extra fittings. The valve handles line pressures up to 350 bar on ports A and X, while port B endures 420 bar, so it can sit directly in high-pressure pump or actuator branches. A separate pilot signal may act on port X to 350 bar, giving designers the option to force open the poppet when required. Flow from A to B starts once the poppet sees a cracking pressure of 2 bar, thereby minimizing energy loss during normal advance strokes. Reverse flow from B to A is restricted until 20 bar is reached, preventing unplanned motion when loads try to overrun the actuator.

An internal orifice of 0.3 mm meters pilot oil so the pre-opening sequence remains stable even with pressure spikes. The pre-opening area ratio of 1:20 further tunes this metering, allowing a small pilot flow to lift a larger poppet area for smooth transition to full flow. During full travel the valve passes up to 80 l/min, covering common feed rates for compact presses or tooling circuits. System cleanliness must be maintained at ISO 4406 class 20/18/15 to protect the sealing edges and avoid premature wear. Compatible hydraulic media are HL or HLP fluids according to DIN 51524, ensuring proper lubrication of the moving parts. Service temperature can rise to 80 °C, so installations must include coolers or reservoirs sized to keep oil below this limit. Sealing elements are made from FKM, improving resistance against heat and mineral oil aging. The assembled unit weighs 7 kg, which supports rigid mounting while still allowing manual handling during maintenance.

Technical Specifications

Cleanliness Level (iso 4406)

20/18/15

Connection Type

SAE Flange

Control Pressure Max (x)

350 bar

Control/measuring Port Thread

G1/4

Cracking Pressure A→b

2 bar

Hydraulic Fluid

HL or HLP (DIN 51524)

Hydraulic Fluid Temp Max

+80 °C

Max Flow

80 l/min

Max Operating Pressure (a,x)

350 bar

Max Operating Pressure (b)

420 bar

Nominal Size

12

Opening Pressure B→a (start)

20 bar

Orifice Diameter

0.3 mm

Pre-opening Area Ratio

1:20

Sealing Material

FKM

Weight

7 kg

Shipping & Payment Options