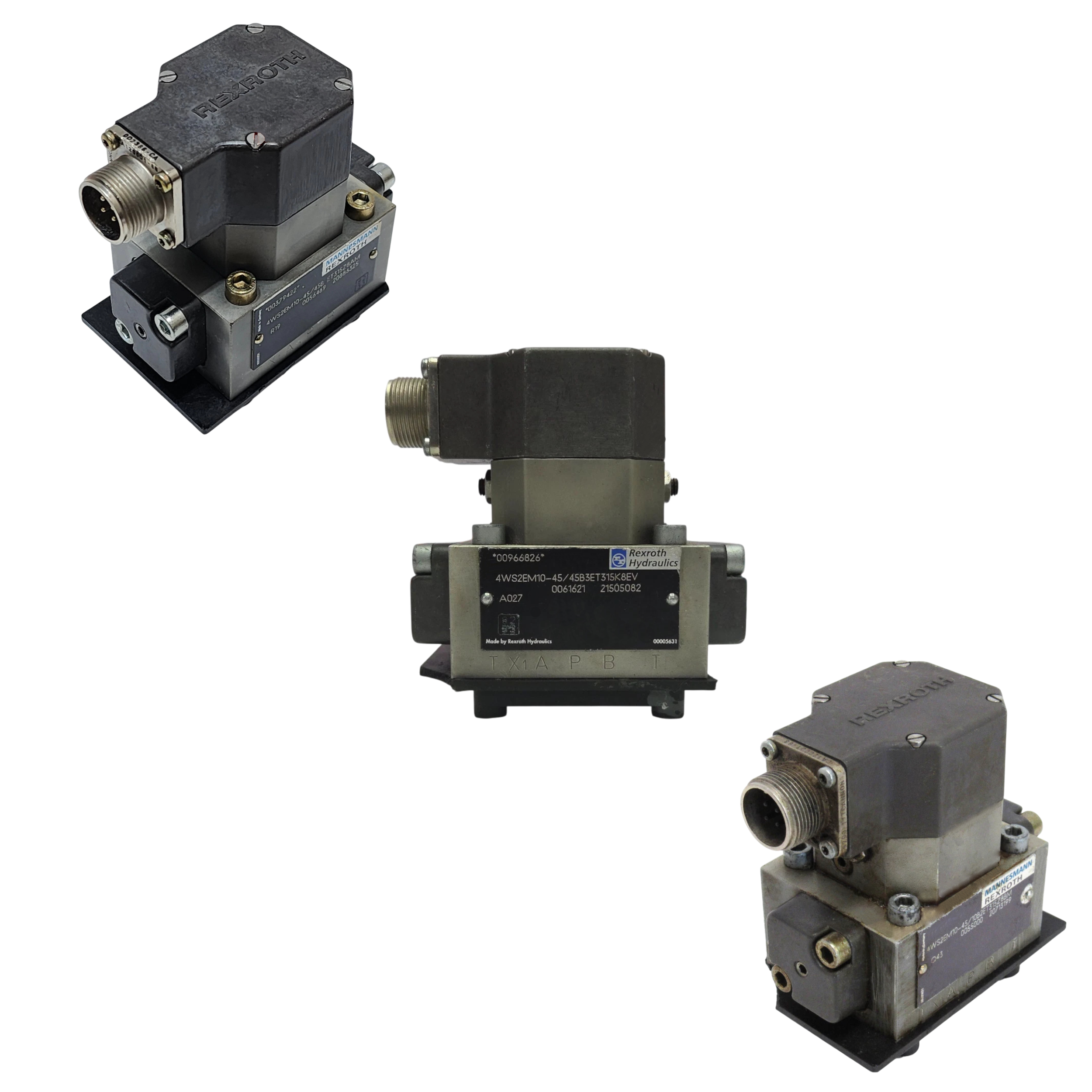

Bosch Rexroth | 4WSE2ED10-5X75B13T315K31EV-102

4WSE2ED10-5X/75B13T315K31EV-102

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The 4WSE2ED10-5X/75B13T315K31EV-102 servo valve is produced by Bosch Rexroth within the 4WS Servo Valves series. It meters hydraulic flow and direction for closed-loop automation where precise position and force control are required. The size 10 (NG10) classification defines a mounting face that matches common manifold ports in medium-capacity circuits. A porting pattern of ISO 4401-05-05-0-05 aligns the valve with standardized subplates so installation is straightforward. Rated flow of 75 l/min at a pressure drop of 70 bar indicates the volume it can regulate without excessive energy loss. The maximum operating pressure of 315 bar allows the valve to function in high-pressure systems common to presses and die-casting machines. Each electromagnetic coil presents a resistance of 85 Ω, setting the electrical load that the drive amplifier must handle. A nominal current of 30 mA per coil produces the magnetic force needed to shift the spool accurately. The command channel accepts a ±10 mA signal, while a measuring output of ±10 mA across a load up to 1 kΩ delivers position feedback for closed-loop control.

The valve electronics operate from a ±15 V supply with a tolerance of ±3 %, providing stable power for the internal position transducer and coils. Connection is made through an EN 175201-804 plug coded K31, which simplifies wiring in modular cabinet designs. An IP65 ingress rating shields internal components from dust and low-pressure water jets so the unit can be mounted directly on machinery. FKM seals protect against standard hydraulic oils and elevated temperatures, maintaining leakage control over long service intervals. System cleanliness must reach ISO 4406 class 18/16/13 to prevent spool wear and maintain dynamic response. The pilot supply can be taken externally, with return through the internal T port, giving designers flexibility in pressure staging. A combined mechanical and electric return system centers the spool and permits electronic monitoring of the home position. The assembled unit weighs 3.65 kg, light enough for manifold mounting without additional support hardware.

Technical Specifications

Coil Resistance

85 Ω

Command Signal (input)

±10 mA

Electrical Connector

EN 175201-804 (K31)

Fluid Cleanliness

ISO 4406 18/16/13

Ingress Protection

IP65

Max Operating Pressure

315 bar

Measuring Output

±10 mA (max 1 kΩ)

Pilot Supply/return

External/Internal (T)

Porting Pattern

ISO 4401-05-05-0-05

Rated Current Per Coil

30 mA

Rated Flow (Δp=70 Bar)

75 l/min

Return System

Mechanical And Electric (D)

Seal Material

FKM (V)

Size

10 (NG10)

Supply Voltage

±15 V ±3%

Weight

3.65 kg

Shipping & Payment Options