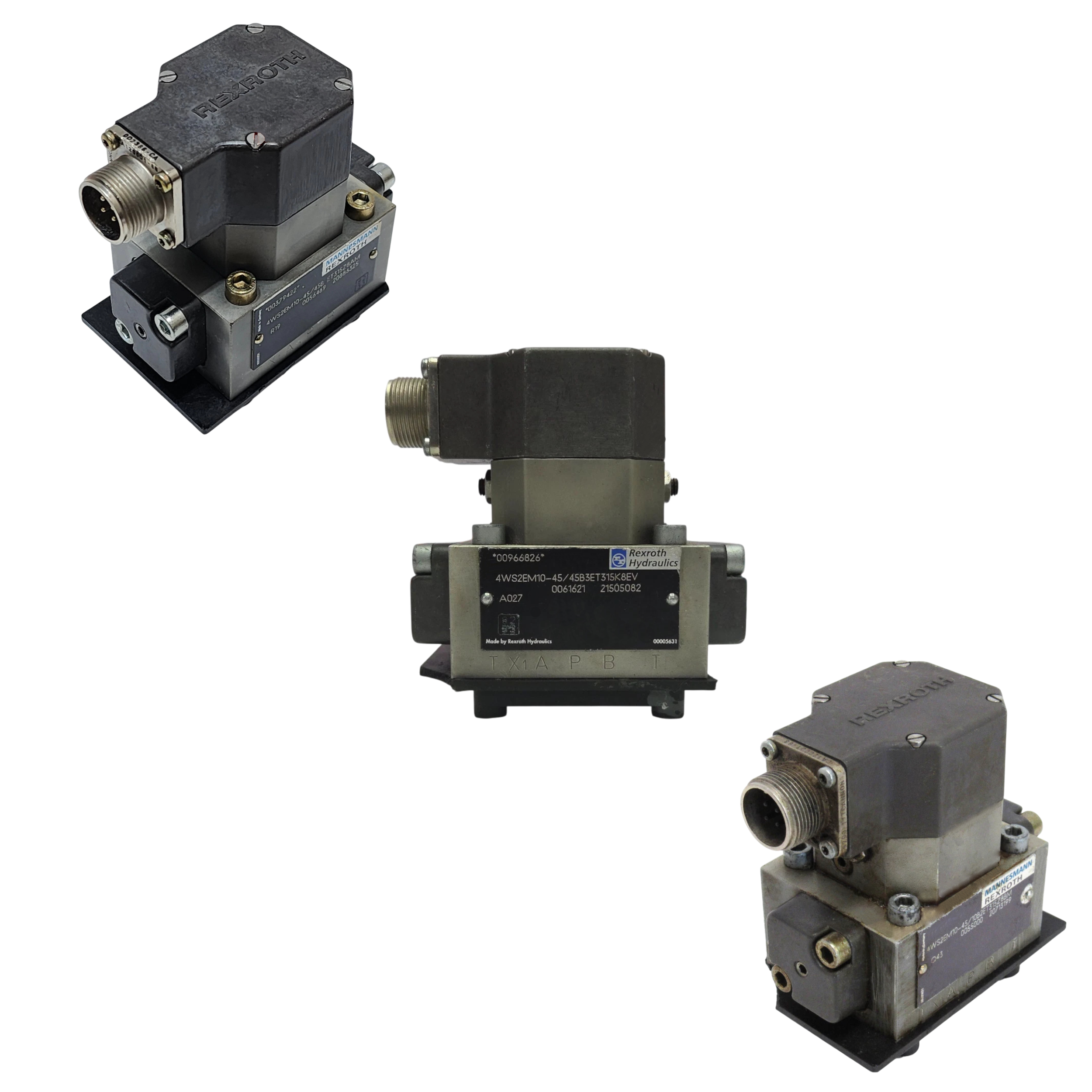

Bosch Rexroth | 4WSE2ED10-5X75B13-315K31EV

4WSE2ED10-5X/75B13-315K31EV

Request a Quote

What Happens Next?

Email Confirmation

You will get an email confirming we have received your inquiry.

Dedicated Account Manager

A team member will review your request and be in touch concerning any questions or specifications.

Quote Delivered

You will receive a comprehensive quote tailored to your specific needs.

The 4WSE2ED10-5X/75B13-315K31EV servo valve is produced by Bosch Rexroth for the 4WS Servo Valves series. It meters hydraulic flow in closed-loop positioning and force control circuits used in industrial automation. The valve is built in size 10 and follows the ISO 4401-05-05-0-05 mounting pattern, so it fits standard subplates without adapter blocks. A rated flow of 75 l/min at a 70-bar differential allows the unit to drive medium-sized actuators, while the maximum operating pressure of 315 bar supports high force cylinders. Mineral oil classified as HL or HLP per DIN 51524 is the intended hydraulic fluid, and system cleanliness must reach class 18/16/13 according to ISO 4406 to preserve spool and nozzle accuracy. Pilot oil is supplied internally with an external return, simplifying line routing, and FKM seals resist heat and aggressive additives. The assembly weighs 3.65 kg, permitting manual installation in compact manifolds.

Electrical interface parameters are matched to common motion controllers: the command signal is ±10 mA, and the measuring output mirrors spool position with the same ±10 mA range for feedback loops. An input reference resistance of 100 Ω ensures correct current scaling, while a maximum supply current of 150 mA protects the coil against overheating. The electronics are powered from a ±15 V supply, which stabilizes the integrated amplifier. Connection is made through a plug built to EN 175201-804, guaranteeing interchangeability with field cables. The return system combines mechanical linkage and electric sensing to relay spool displacement, enhancing redundancy. Both hydraulic and electrical conductors remain inside the manifold footprint due to the compact housing, allowing precise flow modulation in servo-controlled presses, injection molding machines, and test rigs.

Technical Specifications

Cleanliness Class

18/16/13 (ISO 4406)

Command Signal

±10 mA

Connector Standard

EN 175201-804

Hydraulic Fluid

Mineral oil (HL, HLP) DIN 51524

Input Reference Resistance

100 Ω

Maximum Operating Pressure

315 bar

Measuring Output

±10 mA

Mounting Pattern

ISO 4401-05-05-0-05

Pilot Oil

Supply internal, return external

Rated Flow (Δp 70 Bar)

75 l/min

Return System

Mechanical and electric

Seal Material

FKM

Size

10

Supply Current (max)

150 mA

Supply Voltage

±15 V

Weight

3.65 kg

Shipping & Payment Options